At last I think I am getting somewhere.

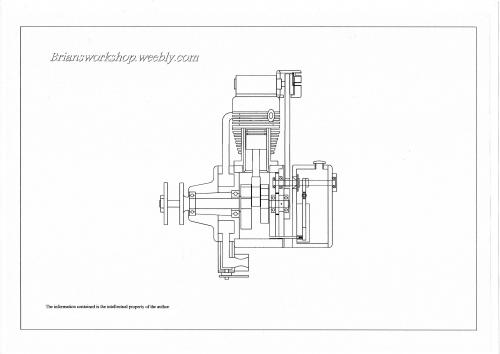

Again this drawing is a montage of all five cylinders. So what is new .

The cylinder and rod are now longer to reduce con rod angularity and allow a better proportioned master rod.

Oil tank is now shorter and will form the mounting for the engine.

Plunger oil pumps driven from the accessory shafts on number 2&5 cylinders, spit and hope lube system.

Distributor on number 3 cam shaft trigger unit on number 4 cam shaft.

Natural gas cab mounted below crank case feeding annular chamber in nose piece.

Prop hub to take 24X12 prop (possibly)

More work to do on tensioner for belts and determining the position of the head studs and the angle of the exhaust port. ETC

But as I do not intend to start cutting metal until the winter I have plenty of time.

Brian

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)