Posts: 716

Threads: 32

Joined: Apr 2012

Location: Washington, USA

12-21-2014, 11:12 AM

(This post was last modified: 12-21-2014, 11:20 AM by Sunset Machine.)

(12-17-2014, 12:32 PM)Black Forest Wrote: (12-15-2014, 09:59 AM)Mayhem Wrote: Embrace the metric system Ken! M8x1.25 is one of the most commonly used taps in my set. Along with M6x1 and M10x1.25.

By the way

Now I know why my M10's seem tight. I always made them 1 or 1.5 pitch! Mmmmmm.....1.25

Throw them things out and go Yankee pitch. They won't do that to you.

We stock both, yankee on the left, metric on the right. The metric cabinet will never be complete because of all the sizes available. What a confusing system, I bet half of them are cross threaded assemblies..

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Personally I disagree with your statement about the metric system being confusing.

Both have what is considered 'standard' fine and coarse pitch threads. Yes, you can have two options for fine metric threads (e.g. M10x1.0 and M10x1.25) but you also have UNEF and UNS in the "Yankee pitch" system. For example, I have at least four different varieties of 5/16" bolts, with 18, 20, 22 and 24 tpi. I also think I have some 5/16-28 but I would have to check.

You may recall that I posted about the different drawbar threads on my NTMB30 tooling for my mill. I have tooling with M12x1.75, 1/2-12 and 1/2-13 pitch threads.

I've grown up using both systems and have no major issues with either system

Hunting American dentists since 2015.

Posts: 8,898

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

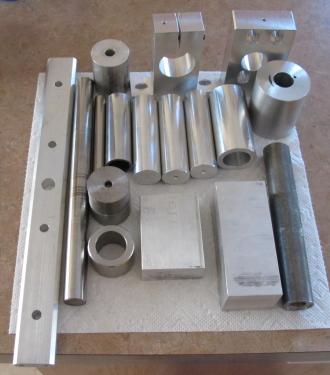

Latest dumpster diving results.

Ed

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

The following 2 users Like f350ca's post:

EdK (01-10-2015), Mayhem (01-10-2015)

Nice score Ed, but the scrap you find even looks too clean. Get some dust and rust on it to make it respectable scrap.

Free advice is worth exactly what you payed for it.

Greg