Posts: 795

Threads: 52

Joined: Mar 2012

Location: Rochester, NY

The following 5 users Like rleete's post:

JScott (02-04-2023), TomG (02-04-2023), f350ca (02-04-2023), EdK (02-04-2023), Vinny (02-05-2023)

Whipped up a couple of keychain things. Brass. A guy at work saw some similar items on the web (round, stainless, silly expensive) and I said I could make them. Funny thing is, the guy works in the tool room, so probably could have made them himself. I bought the key rings from a local craft store.

To finish, I used my new deburring wheel, purchased from Amazon: Amazon.com: AmaCupid Deburring Wire Drawing Wheels, Nylon Fibe Wheel 6 inch 5P Hardness. for Bench Grinder Buffing Machine Polishing Copper, etc.Aluminum Oxide Abrasive.80 Grit, 1/2 inch Mandrel,1 inch Thickn : Industrial & Scientific

They are about 12 bucks. They work great, giving a nice, brushed finish on everything I've tried. I would highly recommend these or something similar. The 3M ones are a bit pricey, but probably last longer. For the price, these can't be beat.

Full of ideas, but slow to produce parts

Posts: 8,889

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Finally got around to making the rods to thread into the holder for holding the washers and nuts.

Ed

Posts: 8,889

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

I needed a bronze or brass washer that was about .037" thick. Not to be found so I ordered one from McMaster that was .060" thick. I super glued it to the end of a rod of aluminum and chucked it up in the lathe and faced it to the rough dimension. Ended up being .033" thick which was acceptable for my application. I popped it off by prying it with an Exacto knife. Worked good.

Ed

Posts: 8,889

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Used my die holder for the first time today to make a quick and dirty arbor. Worked good.

Ed

Posts: 8,889

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

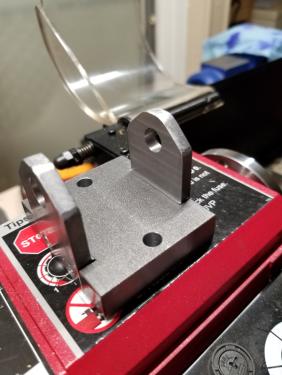

I finally got back into the shop and finished the bracket for the DRO arm. I'm going to paint it black to match the brackets that I bought from Precision Matthews.

Ed

Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

The following 2 users Like Vinny's post:

EdK (03-15-2023), Highpower (03-15-2023)

I'm guessing that's 3D printed? If not, it looks like it'd hold up a car.

Posts: 8,889

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

rleete (07-25-2023)

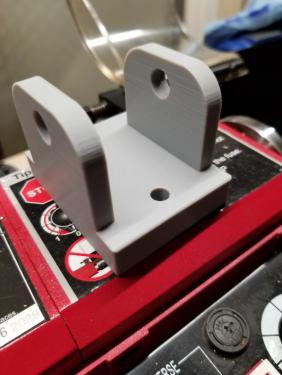

(03-14-2023, 10:54 PM)Vinny Wrote: I'm guessing that's 3D printed? If not, it looks like it'd hold up a car.

That's the "hold up a car" version.

Here's the 3D printed version.

Ed

Posts: 795

Threads: 52

Joined: Mar 2012

Location: Rochester, NY

How did you get that surface finish?

Full of ideas, but slow to produce parts

Posts: 8,889

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(03-15-2023, 08:22 AM)rleete Wrote: How did you get that surface finish?

It's cold rolled steel. That's the finish it had when I bought it. It looks like it was bead blasted in the picture.

Ed

Posts: 8,889

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Worked on the t-nuts using the DRO. It sure was nice to be able to go from hole to hole with each tool instead of doing all of the work on each hole one at a time. Saves a lot of time.

Ed

|

That's the "hold up a car" version.

That's the "hold up a car" version.