Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Got'r done! After lunch I'm going to clean off the lathe and dismantle it and reassemble it with the new parts. I might have to shorten the screws so they're flush with the disk. I'll find out when I go to assemble it.

Ed

Posts: 794

Threads: 52

Joined: Mar 2012

Location: Rochester, NY

That would bug me no end, even if I never disassembled it ever again.

Chuck them up in the lathe and face them off to the same length.

Full of ideas, but slow to produce parts

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

rleete (06-04-2024)

(06-04-2024, 03:11 PM)rleete Wrote: That would bug me no end, even if I never disassembled it ever again.

Chuck them up in the lathe and face them off to the same length.

Here you go Roger. I just removed them and filed them down. Much quicker than installing the 4-jaw chuck.

Ed

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

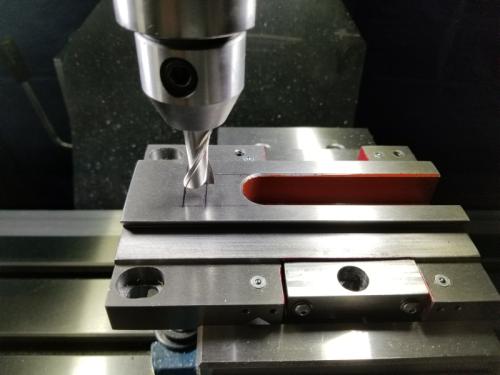

All done except for the bronze gib. That's a separate project in itself. That's going to take some thinking as to how to hold it to machine the angles.

Ed

Posts: 794

Threads: 52

Joined: Mar 2012

Location: Rochester, NY

What? You don't have a surface grinder and a Herman-Shmidt angle vise? Your tool crib is lacking...

Full of ideas, but slow to produce parts

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

Highpower (06-05-2024)

(06-04-2024, 04:56 PM)rleete Wrote: What? You don't have a surface grinder and a Herman-Shmidt angle vise? ...

Not yet.

I do want to make a lantern chuck for shortening screws. I've been studying plans I found online to come up with my own design. I've wanted to make one of those for years.

Ed

Posts: 794

Threads: 52

Joined: Mar 2012

Location: Rochester, NY

Well, post the plans. It's always been on my list for #6 and smaller screws.

Full of ideas, but slow to produce parts

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(06-05-2024, 09:48 AM)rleete Wrote: Well, post the plans. It's always been on my list for #6 and smaller screws.

Will do. My plan is to make it useful for 1/4" and smaller screws.

Ed

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 5 users Like EdK's post:

JScott (06-11-2024), Vinny (06-11-2024), f350ca (06-11-2024), rubes (06-12-2024), arvidj (06-13-2024)

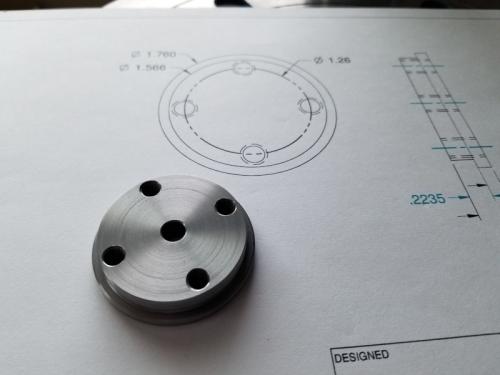

Installing the AXA tool post reduced the diameter of work that I could machine in the lathe so I'm doing the extension mod. I bought the longer length cross slide feed screw from LMS. They wanted $40 for the spacer & I'm not willing to pay that amount for a simple spacer so I'll make my own.

Ed