Posts: 124

Threads: 14

Joined: Jan 2016

Location: North Vancouver, Canada

(12-05-2016, 01:43 AM)IPete O Wrote: I slight hijack if I may, I want to strip and paint my mill whilst I have some time off over January. The enamel I used on my lathe did not stand up at all to cutting fluids so I won't be using that again. Rustoleum has been recommended here but when I look at their website, there are a thousand different products under the brand name. Wondering what particular product I should be looking at? If I can get anything like as good a finish as John's mill I will be very happy, especially if it stays that way after exposure to coolants.

Do you have access to DuPont paints where you are? If so I can tell what I used. Let me know

Cheers

John

Posts: 2,328

Threads: 271

Joined: Jun 2014

Location: La Libertad, Philippines

(12-05-2016, 01:43 AM)Pete O Wrote: I slight hijack if I may, I want to strip and paint my mill whilst I have some time off over January. The enamel I used on my lathe did not stand up at all to cutting fluids so I won't be using that again. Rustoleum has been recommended here but when I look at their website, there are a thousand different products under the brand name. Wondering what particular product I should be looking at? If I can get anything like as good a finish as John's mill I will be very happy, especially if it stays that way after exposure to coolants.

I used Rustoleum Industrial Grey and it looks and stands up very well. Apply in thin multiple coats.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

(12-05-2016, 11:07 AM)Old Minger Wrote: (12-05-2016, 01:43 AM)IPete O Wrote:

Do you have access to DuPont paints where you are? If so I can tell what I used. Let me know

Cheers

John

Thanks John, I'm sure I can source DuPont coatings here, a product name would be great.

Thanks

Pete

(12-05-2016, 02:20 PM)Dr Stan Wrote: I used Rustoleum Industrial Grey and it looks and stands up very well. Apply in thin multiple coats.

A search for 'Rustoleum Industrial Grey' brings up a bewildering array of industrial products but none specifically by that name, closest thing seems to be spray cans but that is not an economical way to go when I have spraying equipment on hand. Perhaps the range available here is somewhat different. I don't trust suppliers here to give good advice on this kind of thing, the local paint supplier gave me a bum steer with the paint for the lathe, looked ok until the first time it met coolant, the coolant acted like paint stripper on it.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 124

Threads: 14

Joined: Jan 2016

Location: North Vancouver, Canada

Pete

In my search for paint for the Bridgeport I had a long old chat with the Rustoleum paint rep. They have an epoxy paint which would suit the purpose and I nearly went with it. However the lack of choices in variations of grey was the reason I went with the DuPont coatings. Same kind of paint but you could dial in your own colour.

The Rustoleum product to look at is the DTM 9100 series. You will find this on their commercial/industrial website or just search for 9100. You will need an activator with it and you can apply with HVLP gun.

The DuPont product I went with is the AXALTA brand and the product is called RIVAL. Again a paint and activator deal and it goes on well. I believe it's a commercial vehicle paint used for tractors and tankers etc anything that is exposed to a lot hydraulic fluid as it's very resistant to that and oils.

Let me know if you want any other info eg the colour mix I used etc.

On a side note I had a result with the black paint as the guys from Machine Builders of New England, the Bridgeport restoration specialist very kindly supplied the info on the paint they use on their restorations. Good guys and very helpful happy to recommend them as a company.

Cheers

John

Posts: 2,328

Threads: 271

Joined: Jun 2014

Location: La Libertad, Philippines

12-07-2016, 01:19 PM

(This post was last modified: 12-07-2016, 01:26 PM by Dr Stan.)

The Rust-Oleum web site is having problems today, but I finally found the paint to which I was referring:

https://www.rustoleum.com/product-catalo...ive-enamel

BTW, I'm not very particular regarding machine tool paint, I'm mostly interested in having my machines look good and function well. The pic of my Fray mill is an example. Changed out the motor from 3 phase to single phase and increased the HP rating. As soon as my foot heals I'll be modifying it so the head faces out, not to the right as it is currently configured.

I'll admit to a color selection that was not well thought out. I used International Harvester white (off white or cream) on a 9" South Bend which showed dirt & grease like you would not believe.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

Thanks for the info fellas, I'm working in an area with a lot of industrial suppliers this week so should be able to track one of those products down. Your colour mix might be handy to know also John, thankyou. The Bridgeport resto looks fantastic- as does your Fray, Dr Stan. I can't get onto the Rustoleum site at all at present but will try again. All good info, thanks again.

(12-07-2016, 12:23 PM)Old Minger Wrote: On a side note I had a result with the black paint as the guys from Machine Builders of New England, the Bridgeport restoration specialist very kindly supplied the info on the paint they use on their restorations. Good guys and very helpful happy to recommend them as a company.

Cheers

John

Not a side note at all OM, your thread, my hijack! Looking forward to more images of your mill.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 124

Threads: 14

Joined: Jan 2016

Location: North Vancouver, Canada

The Bijur lubrication parts arrived so I fitted them which was fairly straight forward. So nothing left to do but fill up the tank and give it a test what could go wrong?

So pulled on the pump handle and oil squirted everywhere you could imagine accept for the oil ways on the saddle and the knee, so some work left to do there.

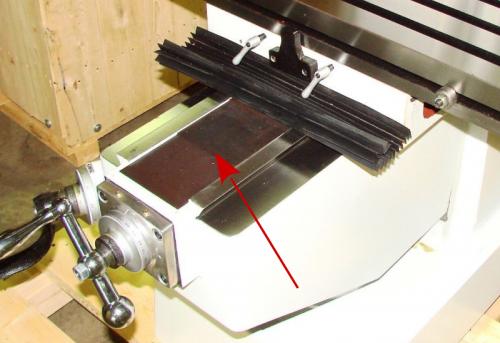

Also decided to have a go and make some kind of chip guard for the knee lift bevel gear. it clears all moving parts that I can see so should I go with it or is there a reason I should not install this?

once I plug the leaks and get the oil flowing to where it should, next will be the table install.

Cheers

John

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Hi John,

That last picture looks like a top view of the saddle. Don't you have the sheet metal guards that cover that hole to prevent swarf from getting down into there?

Ed

Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

The following 3 users Like Vinny's post:

f350ca (12-15-2016), Pete O (12-16-2016), rleete (12-16-2016)

(12-15-2016, 10:04 AM)Old Minger Wrote: So nothing left to do but fill up the tank and give it a test what could go wrong?

Every time I read or hear a comment like that having to do with fluids and a pump I picture someone shrieking: "SHUT IT OFF!!! SHUT IT OFF!!!"

Posts: 124

Threads: 14

Joined: Jan 2016

Location: North Vancouver, Canada

(12-15-2016, 06:04 PM)EdK Wrote: Hi John,

That last picture looks like a top view of the saddle. Don't you have the sheet metal guards that cover that hole to prevent swarf from getting down into there?

Ed

Ed your absolutely right my Bridgeport does have those covers. I was just going by the amount of chips I had to shovel out of the knee when I took it apart. You literally couldn't see the gear mechanism because of the amount of chips down there. Do you think I should keep it?

|