Hi there,

I bought a short bed version of the Concord 460 about 15 years ago.

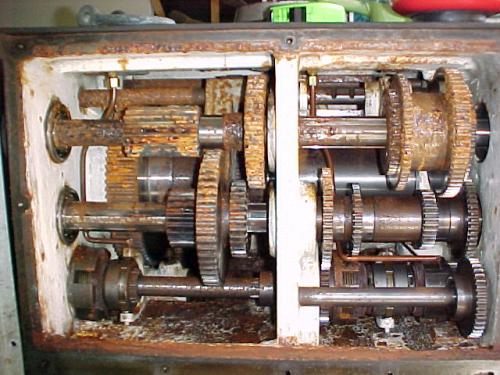

Mine had been "stored" under a cheap cover outside and forgotten for several years.

![[Image: image.gif]](http://www.metalworkingfun.com/images/attachtypes/image.gif)

The cover had disintegrated and the rain had gone into the gearboxes via the speed change gear levers and the oil distribution galleries. So water was distributed through everything important in the headstock and "Norton" box. There was so much water that there was no oil left in the oil tank under the machine.

(I have attempted to insert before and after photos of the headstock gearbox and one spindle cup race after cleaning but before regrinding, but cannot figure out how to control their placement.)

Needless to say I got it very cheap and a new replacement Timkin taper roller bearing (one cone only) for the spindle, cost as much as the lathe did!

![[Image: image.gif]](http://www.metalworkingfun.com/images/attachtypes/image.gif)

After a complete dismantle, and electrolysis cleaning of the headstock and Norton gearboxes (gears, shafts, bearings etc), plus removal of rust from the rest of the machine, it has turned out to be a really nice accurate machine to use.

![[Image: image.gif]](http://www.metalworkingfun.com/images/attachtypes/image.gif)

Removing the spindle was a challenge, as it looks like they assembled the bearings on the spindle and then pressed the assembly into the headstock. I had to cut the big key in the largest gear on the spindle into several pieces about an inch long, (while still in place), in order to get the spindle out of the gears and bearings.

![[Image: image.gif]](http://www.metalworkingfun.com/images/attachtypes/image.gif)

Then on reassembly I had no specs for things like spindle bearing preload, so had to guess them by what felt likely.

Haha, I also learnt the hard way, about the oil held in the cover. Luckily I had already removed the power switch box by this stage, but I did notice the switch box was damp with oil inside.

As I can only get single phase power here I've been driving it with a 3 hp single phase motor. I had to back off the clutches as much as reasonable (which took many adjustments), to try to reduce the clutch drag as much as possible, as the motor is struggling!

Ultimately I'll put a single phase to three phase electronic drive, and reinstall the original 12 hp motor.

However it has done a range of odd ball jobs, from re-machining trailer axil seal surfaces, (the big spindle bore allowed the axil to be passed through the headstock), to mostly, machining stationary engine parts; ie a new 24" flywheel, 7' dia (by 16" long piston), ring grooves and rings, and down to ignition hot tubes in Stainless Steel.

I only stumbled on this thread yesterday and was reading it with great interest, but found it stopped suddenly, just as it was getting interesting.

I'd love to hear how the rest of it went, did you get it sorted and set up, how has it been over the years since 2016?

I hope it went well.

Cheers

Darryl

![[Image: image.gif]](http://www.metalworkingfun.com/images/attachtypes/image.gif) The cover had disintegrated and the rain had gone into the gearboxes via the speed change gear levers and the oil distribution galleries. So water was distributed through everything important in the headstock and "Norton" box. There was so much water that there was no oil left in the oil tank under the machine.

The cover had disintegrated and the rain had gone into the gearboxes via the speed change gear levers and the oil distribution galleries. So water was distributed through everything important in the headstock and "Norton" box. There was so much water that there was no oil left in the oil tank under the machine.

to the forum Darryl.

to the forum Darryl.