Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

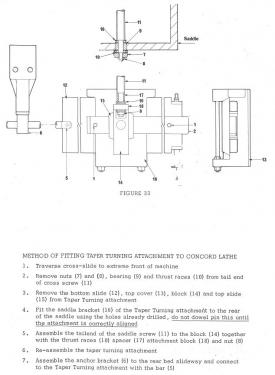

Here is the section of the manual that I think holds the key:

As for the panels, I'm not quite sure yet. I need to look into what is available.

Hunting American dentists since 2015.

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

The following 1 user Likes f350ca's post:

Mayhem (05-25-2015)

Darren, a lot of the components on your lathe seam similar to my Summit (made in Poland) The taper attachment on mine uses a spline off the handle so that the taper attachment is functional all the time, nice feature. On mine the attachment has to be there to anchor the lead screw even if your not using the taper attachment. When you want to cut a taper you anchor the slide to the bed and the taper pulls the lead screw and cross feed with it.

Free advice is worth exactly what you payed for it.

Greg

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Thanks Greg - could you take a picture of yours please? I really haven't any experience (or knowledge really) of these.

Also, I just realized that there is a required spacer that isn't in the 'normal' part list of the leadscrew. I need to take a closer look but have more pressing things to sort out. Primarily to loss of drive since adjusting the clutches. I guess I screwed that one up

I just tell myself it is character building

I don't think that parts are available for this any more, so my hope is that I can either find someone with one who would be willing to take pictures and measurements, or find a source for drawings. I may try PM but when I searched Elliott Concord over there, I only got a few hits. I probably will still try though.

Hunting American dentists since 2015.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

The following 1 user Likes PixMan's post:

Mayhem (05-26-2015)

Loss of drive? Adjust the clutches back to where they were and try again?

It's all good education. I should take apart the apron on my lathe so sort out the automatic way lube system, but I'm blissfully just slathering the way lube manually for years now.

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

Free advice is worth exactly what you payed for it.

Greg

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Ken - I'll certainly be trying to sort out my stuff up

Greg - thanks, I'll study them when trying to figure mine out. As I said previously, I think I will remove the splash guard before I do that.

Hunting American dentists since 2015.

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

Probably a good idea, its a bugger even reaching over it to set the taper attachment up. One of the drawbacks with larger lathes, your always stretching to see something or pick up the thread wire you dropped.

Free advice is worth exactly what you payed for it.

Greg

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The slide out chip trays will help me in finding those thread wires Greg. Actually, I could probably slide one out and lay on my creeper and access the attachment/rear of the cross slide that way. I may have to try that

Hunting American dentists since 2015.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

until you get it cleaned up and running why not leave it far enough from the wall to walk around it.

DA

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

I just tell myself it is character building

I just tell myself it is character building

![[Image: IMG_0278.jpg]](https://lh3.googleusercontent.com/-vFMBGvHL8cQ/UInIrVhORoI/AAAAAAAAC-8/w6KZr7nNffM/s512/IMG_0278.jpg)

![[Image: IMG_0279.jpg]](https://lh3.googleusercontent.com/-jaArr6QGc2o/UInIsR_gOpI/AAAAAAAAC_A/WUN-fM0Qf-Y/s512/IMG_0279.jpg)

![[Image: IMG_0283.jpg]](https://lh3.googleusercontent.com/-cIM7AaF_QnE/UInIsNAUmvI/AAAAAAAAAqY/oAnbybVikHE/s512/IMG_0283.jpg)

![[Image: IMG_0284.jpg]](https://lh3.googleusercontent.com/-JNIOZIGqkvY/UInItDqiocI/AAAAAAAAC_E/oqplCiX38Yg/s640/IMG_0284.jpg)

![[Image: IMG_0285.jpg]](https://lh3.googleusercontent.com/-cYBAhzrK8qM/UInIt1qC-9I/AAAAAAAAC_I/SYOmPOm4EXI/s640/IMG_0285.jpg)

![[Image: IMG_0286.jpg]](https://lh3.googleusercontent.com/-Np11GjqZaaU/UInIuFaqUwI/AAAAAAAAC_M/1QLVpdIdLZQ/s512/IMG_0286.jpg)