Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

Back in the day (longer than I can remember) I was into tropical fish as well as metalworking.

I got to work one day making some aquarium stands out of angle Iron.

After cutting the 45° cuts and the 90° ones I calculated the number of feet I had cut with a hacksaw and, after the stands were welded and the paint was drying, I started making a power hacksaw.

Good thing I did 'cause some folks at the aquarium society I was a member of got wind of the fact that I could build stands (even 2 tiered stands with shelves for smaller tanks on top, larger in the middle and more larger tanks or storage on the bottom shelf (about 3" off the floor).

The little power hacksaw served me well for several years before the bandsaw and other interests took over.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 240

Threads: 30

Joined: Mar 2014

Location: Planeta Rica, Colombia

The following 1 user Likes JScott's post:

EdK (09-17-2014)

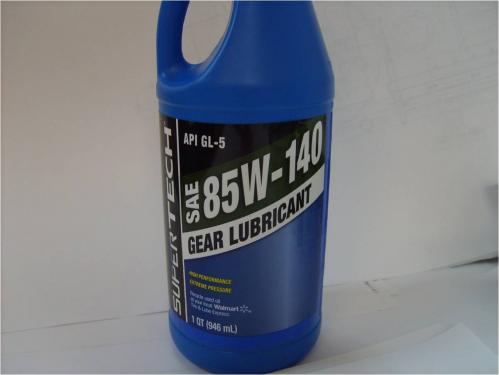

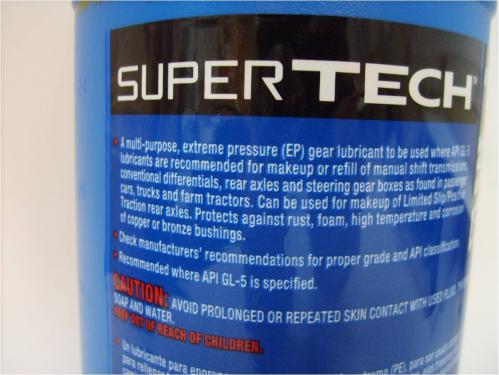

I snooped around the interwebs and found an old thread about gear oil at WalMart that was "yellow metal safe". Popped in and sure enough their 85W-140 Super Tech brand has a printed statement on the label that it is safe and protects against corrosion of copper or bronze bushings. Its labeled API GL-5 Extreme Pressure so it should work fine.

The price was right so I bought a quart to do an oil change on the band saw gear box after I run it a few hours.

JScott, proud to be a member of MetalworkingFun Forum since Mar 2014.

Posts: 15

Threads: 2

Joined: Mar 2015

Location: Kansas

Bought the same Harbor Freight band saw a couple of weeks ago cuts nice & square.

Posts: 691

Threads: 14

Joined: Feb 2015

Location: Oakland, California

06-23-2015, 10:58 PM

(This post was last modified: 06-23-2015, 11:01 PM by Roadracer_Al.)

I have had my HF saw for over 20 years.

It was pretty awful right out of the box: it arrived with a couple of the plastic handles smashed, and required a lot of tinkering to make it stop throwing blades. The next ~17 years were pretty good, and over the last 3 years, it had started throwing blades again.

Turns out that the cast iron wheels had worn into a bit of a cone shape and the top wheel bearing and axle were just plain worn out & wobbly. Some quality time on the lathe -- I turned the original top wheel axle so it was nicely finished & cylindrical again, then made a mating bronze bushing to match the now-odd size. Then I made a mandrel which centered the wheel, and gave the OD a light skim to bring it back to cylindrical and concentric again. Some new bronze washers to get the alignment better, and a normal bandsaw tuneup, and it's better than new... it keeps the blades on, which it didn't when new!

IMHO, the two best mods I made were to put a 4" long 7/16" OD jack screw on the clamp so it will hold small work better, and making a stout base from 1" square tube stock which accommodates a full-sheet bakery pan to catch chips in both the horizontal & vertical orientation. The pan helps keep the shop from getting quite so filthy. It's also about 6" higher than the stock base, which is nice, too.

Next mod is going to be an old Luxo type desk lamp attached to the base.

I'll never forget what a family friend who ran a commercial kitchen fabricating business said about all saws: the blade IS the tool, buy good blades. That said, Starrett blades tend to be a bit harder, therefore, the teeth break easily if you do a lot of sheet or tube work, but are **awesome** on solid work. Irwin blades are pretty good all around.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

I'm still upset with Irwin for moving manufacture of the Vise Grip line they bought offshore and quality suffering. As a result, I won't buy much (if any) of their stuff.

On my MSC Taiwanese 7x12 bandsaw I use Lenox Classic bi-metal blades, and keep two handy. One is a 10-14 mixed tooth, the other a 4-6 mixed tooth. They really hold up fantastic, and PLOW through every material I've thrown at them.

Posts: 794

Threads: 52

Joined: Mar 2012

Location: Rochester, NY

The following 1 user Likes rleete's post:

DaveH (06-24-2015)

(06-23-2015, 10:58 PM)Roadracer_Al Wrote: the blade IS the tool, buy good blades. That said, Starrett blades tend to be a bit harder, therefore, the teeth break easily if you do a lot of sheet or tube work, but are **awesome** on solid work. Irwin blades are pretty good all around.

I will second that. Starrett blades (obtained from work for free from the leftover pieces) have served me well. If your saw starts to cut crooked, replace (and readjust) the blade. No sense in fighting the tool that is supposed to save you time and effort.

Full of ideas, but slow to produce parts

Posts: 3,799

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

Starrett blades are good, as well as Morse and Lenox, both I believe still made in the U.S.

Tom

Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

I use Morse. Very satisfied.

Posts: 482

Threads: 89

Joined: Oct 2012

Location: camillus (syracuse), ny

When I sold my HF 4 x 6 saw and bought a Wilton 7 x 12 saw, I went to using a Morse blade (the pare that came with the saw). That's all I use now, luckily for me the Wilton uses the same 93-1/2" x 3/4" blade as my vertical Rockwell/Delta 14" metal cutting bandsaw, so I now only have to stock one size spare blade.

jack

Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

I have a blade welder so I make them as I need them. I bought a 125' reel of blade on ebay fairly inexpensively and make them as I need them. The welder hasn't paid for itself yet since I bought the reel, cuze the Morse blade lasts so long.

|

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)