09-16-2014, 01:49 PM

I borrowed a band saw from my friend last week and my wife asked me why don't you just buy one for yourself. I had a 25% off coupon from Harbor Freight so here are some pics of my latest addition to the shop. I have plenty of "odd" steel pieces laying around that will go through this 4x6 band saw to be made useable for machining on the lathe and mill.

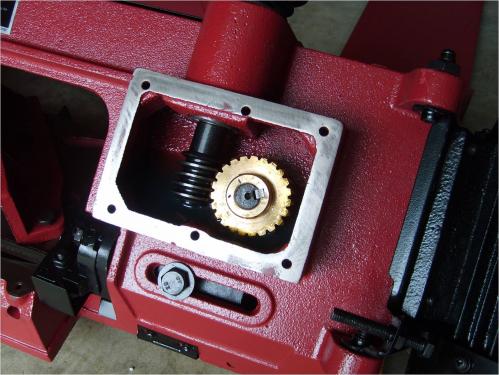

I checked the gearbox and it does not have any sand or casting debris. The oil looks clean but I will probably run it for a few hours and then change it if I can find some "yellow metal safe" gear oil.

So far this saw runs pretty quietly but I may upgrade the belt and fab a more substantial stand when time permits.

I checked the gearbox and it does not have any sand or casting debris. The oil looks clean but I will probably run it for a few hours and then change it if I can find some "yellow metal safe" gear oil.

So far this saw runs pretty quietly but I may upgrade the belt and fab a more substantial stand when time permits.

JScott, proud to be a member of MetalworkingFun Forum since Mar 2014.