Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Hi Darren,

I couldn't find any Patent, I also think if it was Patented they would say so.

I'm sure they don't mind (too much) me copying their design it is just for me.

Swagoffroad have got a bit of free advertising on here, plus Ed bought one. If I could get it for the same price as Ed I would buy one.

DaveH

Posts: 8,886

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Dave,

Ahhh, that U-channel which isn't actually U-channel. I'll post the dimensions for that part this evening.

Ed

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

06-10-2014, 08:21 AM

(This post was last modified: 06-10-2014, 08:22 AM by DaveH.)

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(06-10-2014, 06:43 AM)EdK Wrote: Dave,

Ahhh, that U-channel which isn't actually U-channel. I'll post the dimensions for that part this evening.

Ed

Thanks Ed, I just need those two dimensions please.

DaveH

Posts: 8,886

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Dave,

Dimension A is 2 9/16" and dimension B is 1 1/4" and the steel is 1/4" thick.

Ed

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Thank you Ed,

DaveH

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

06-11-2014, 08:04 AM

(This post was last modified: 06-11-2014, 08:06 AM by Mayhem.)

(06-10-2014, 06:43 AM)EdK Wrote: Dave,

Ahhh, that U-channel which isn't actually U-channel. I'll post the dimensions for that part this evening.

Ed

Ed - do you mean that you call it something different in the US or that it isn't actually u-channel?

Here we would call that c-channel, as when used horizontally the cross-section looks like this: [ (essentially a C). Is it a cheaper alternative to I beam

Hunting American dentists since 2015.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

The reason for the dimensions is to give me an idea how the angle fitted. I have to say it would not be my first suggestion to hold the angle iron.

DaveH

Posts: 8,886

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(06-11-2014, 08:04 AM)Mayhem Wrote: Ed - do you mean that you call it something different in the US or that it isn't actually u-channel?

Here we would call that c-channel, as when used horizontally the cross-section looks like this: [ (essentially a C). Is it a cheaper alternative to I beam

Darren,

No, all I meant was that Swag Offroad didn't purchase C-channel to make the press brake. They bent it out of flat plate. Maybe just semantics and I'm probably wrong, as usual.

Ed

Posts: 738

Threads: 34

Joined: Feb 2012

Location: Minneapolis, MN

Dave,

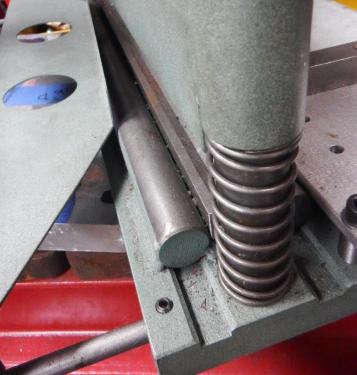

On mine the "bottom die" is held in place between two round shafts that are welded to the base.

The "bottom die" is left in place when bending relatively light weight materials and is removed ... leaving just the two round shafts to act as the "bottom die" ... when bending relatively heavy weight materials.

I'm not suggesting it is the correct\better\best\only way to do anything, just offering it as food for thought.

Arvid