Another thing I want to make (besides 'the most expensive log splitter in the world') is a press brake for my 20 ton hydraulic press.

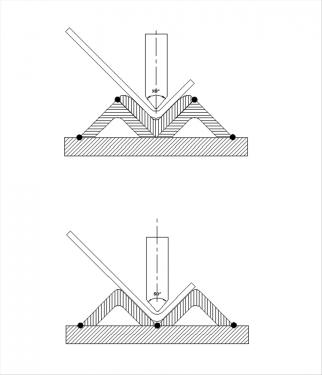

The black circle represent welds. Showing a 3mm thick piece of steel.

Initially I was going to make it like the top sketch, now I am wondering if I really need the centre angle iron and make it like the bottom sketch.

The angle iron will be about 1"x1/4" or likely 30mm x 6mm. Bending 1mm to maximum of 5mm thick steel but most will be 2 to 3mm thick. They don't do 30x6 anymore so it will either be 40x6 or 30x5.

I'm open to comments and suggestions (excepting Steve - he'll want me to make it out of 1" thick boiler plate )

)

I'm just kidding Steve your comments are always welcome as are anyone's.

DaveH

The black circle represent welds. Showing a 3mm thick piece of steel.

Initially I was going to make it like the top sketch, now I am wondering if I really need the centre angle iron and make it like the bottom sketch.

The angle iron will be about 1"x1/4" or likely 30mm x 6mm. Bending 1mm to maximum of 5mm thick steel but most will be 2 to 3mm thick. They don't do 30x6 anymore so it will either be 40x6 or 30x5.

I'm open to comments and suggestions (excepting Steve - he'll want me to make it out of 1" thick boiler plate

)

)I'm just kidding Steve your comments are always welcome as are anyone's.

DaveH