Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

I'm jealous of the bore, my logan is only 3/4". Another good thing about logan lathes is the availability of parts and Scott Logan.

Posts: 2,328

Threads: 271

Joined: Jun 2014

Location: La Libertad, Philippines

(09-21-2016, 05:08 PM)Vinny Wrote: I'm jealous of the bore, my logan is only 3/4". Another good thing about logan lathes is the availability of parts and Scott Logan.

It sure is handy. I can chuck up a 4' long piece of 1 1/2 or 1 5/8" material WO needing any additional support.

I think the 14 1/2" SB had maybe a 1" bore, but it could have been smaller. I know the 9" SB was a lot smaller.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

(09-21-2016, 12:46 PM)Dr Stan Wrote: Yes the Logans were an industrial grade machine, far stouter than the SBs. My SBs were quite long in the tooth so I no longer have to use "wind-age" for anything closer than .005" Holding .0005" is not difficult with the Logan.

BTW, the spindle bore is 1.625" or 41.275 mm in the civilized measuring system.

The Logan you have is one of the more rigid ones I've seen (and worked on.) Don't take offense but they aren't really close to the "industrial grade" ones I've run. An American Pacemaker, LeBlond NFL, Cincinnati tray top, Mori Seiki, Okuma LS, Monarch C, Meuser and dozens more are significantly more robust. I've run all but one of those (the Mori Seiki) and they are in different class altogether. Yours is often found in the "toolroom" of some maintenance departments of big companies as a support shop, so it's what I might consider a "commercial grade" but not something often found in everyday production.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

(09-21-2016, 12:46 PM)Dr Stan Wrote: BTW, the spindle bore is 1.625" or 41.275 mm in the civilized measuring system.

I'll have to go check mine. I know my old lathe had a 3" spindle bore. The new one is a bit bigger

Hunting American dentists since 2015.

Posts: 62

Threads: 30

Joined: Jan 2017

Location: Australia

The following 3 users Like toglhot's post:

EdK (01-18-2017), f350ca (01-18-2017), Mike E. (07-22-2017)

01-17-2017, 07:48 PM

(This post was last modified: 01-17-2017, 07:49 PM by toglhot.)

![Filename: P_20170118_102938[1].jpg

Size: 554.77 KB

01-17-2017, 07:45 PM](attachment.php?thumbnail=14112)

Here's my lathe. It's an Optimum Maschinen re-badged as Impala. 280mm swing and 700mm between centres and with a 25mm spindle bore. It cuts both metric and imperial threads via change gears and a 3 speed gearbox. It came with one of those horrible sheet metal stands which I discarded and replaced with one I made. As Asian lathes go, this is one of the best, I've had two Taiwanese and three Chinese lathes. Castings and machining are excellent and there's no bog/filler. I've made a few mods for it: stand, way protector, coolant system, ball turner, scissor knurler, carriage, cross and top slide locks, etc. Best lathe of the five I've had.

Posts: 2,328

Threads: 271

Joined: Jun 2014

Location: La Libertad, Philippines

(09-21-2016, 08:34 PM)PixMan Wrote: The Logan you have is one of the more rigid ones I've seen (and worked on.) Don't take offense but they aren't really close to the "industrial grade" ones I've run. An American Pacemaker, LeBlond NFL, Cincinnati tray top, Mori Seiki, Okuma LS, Monarch C, Meuser and dozens more are significantly more robust. I've run all but one of those (the Mori Seiki) and they are in different class altogether. Yours is often found in the "toolroom" of some maintenance departments of big companies as a support shop, so it's what I might consider a "commercial grade" but not something often found in everyday production.

I fully agree the Logan is not in the class of the larger lathes you cite as I too have run Pacemakers, Cincinnati tray tops, Monarchs, Sidney's, and other 16" & larger lathes including a Lodge & Shippley 24 X 120 (36 with the gap bed out).

However we also used Logans on board ship & industry when it was appropriate and they can hold the same tolerances. Other than schools the only place I ran SB's was in a sweat shop. BTW, 14" Jets are another story, junk from the beginning. Brand new and required main motor replacements, coolant motor replacements and the paint fell off like it had been applied over the top of oil/grease all in less than 6 months.

Posts: 3,799

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

(01-17-2017, 07:48 PM)toglhot Wrote:

Here's my lathe. It's an Optimum Maschinen re-badged as Impala. 280mm swing and 700mm between centres and with a 25mm spindle bore. It cuts both metric and imperial threads via change gears and a 3 speed gearbox. It came with one of those horrible sheet metal stands which I discarded and replaced with one I made. As Asian lathes go, this is one of the best, I've had two Taiwanese and three Chinese lathes. Castings and machining are excellent and there's no bog/filler. I've made a few mods for it: stand, way protector, coolant system, ball turner, scissor knurler, carriage, cross and top slide locks, etc. Best lathe of the five I've had.

A nice, stout little lathe. What do you have for turning balls?

My mill was made in Taiwan and the castings are very good. The only complaint I have is that they painted it an ungodly shade of green.

Tom

Posts: 691

Threads: 14

Joined: Feb 2015

Location: Oakland, California

Ha. Yes, my Taiwan-made lathe is an ugly shade of green as well.

Posts: 62

Threads: 30

Joined: Jan 2017

Location: Australia

01-18-2017, 05:59 PM

(This post was last modified: 01-18-2017, 06:19 PM by toglhot.)

I've made a couple of ball turners, half a dozen tool holders and tangentials. I've posted two ball turners under the 'General Metalworking Discussion' heading.

Posts: 30

Threads: 4

Joined: May 2017

Location: England

The following 4 users Like Andy T's post:

DaveH (05-15-2017), EdK (05-15-2017), Dr Stan (05-15-2017), Mike E. (07-22-2017)

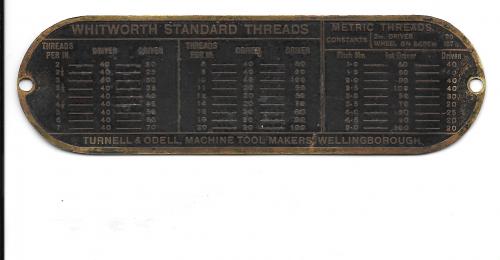

Hi all, new here and this is my first metal working lathe. It's cleaned, painted and in bits waiting on reassembly at the moment.

The machine change gear plate has the name "Turnell & Odell" on it, I've looked on the web and found nothing about this lathe, I would guess it's made around 1920 ish has a 4 1/2" swing over the bed and around 12" between centers. All but 1 of the change gears are missing, the only one I have is a 20 tooth with a 3/4 bore 3/4 thk and 1.390 dia, if this matches any othe change gears from other lathes please let me know.

I think it also had a dog clutch on the lead screw linked to the half nut lever but all parts for that are missing.

I'll post more pics when it's back together

https://www.youtube.com/watch?v=vKbqlYdY3OU

|

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)