Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

(05-30-2013, 08:00 AM)stevec Wrote: (05-29-2013, 06:38 PM)f350ca Wrote: What bent?

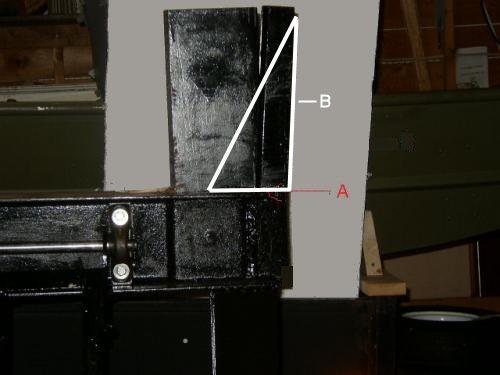

Here's a couple of pics of the bend/tear and potential repair.

In the second pic the red arrow "A" shows the tear at the weak point.

The white triangle "B" shows the possible "gusset" solution.

Steve, I don't know that a gusset as drawn would do you any good without more I-beam behind it to support it.

I'm not an engineer (I'm not even a conductor...) so my opinion is worth exactly what you paid for it.

Maybe consider this as an alternative?

Willie

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

(05-30-2013, 08:30 AM)f350ca Wrote: For reference what size and height is the backer?

Greg, the backer is (was) 18" tall, 6" for the H-beam so it's as tall as the splitting face of the wedge 12"

3 pcs welded as below.

The sides are 1/2" x 2'' x 18", the centre is 5/8" x 1¼" x 18"

The sides are beveled 45° where the split log will be further spread.

The weak part is where I notched the backer to fit the top of the H beam. I figured my weld would restore it's strength, not so much.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

put more edge on your wedge, from what I can see in the picture it looks like a dull butter knife.

Where did the backer bend at the top of the beam or thru the pocket as the wedge rolled backwards.

DA

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

05-30-2013, 09:33 AM

(This post was last modified: 05-30-2013, 09:34 AM by stevec.)

(05-30-2013, 09:10 AM)Highpower Wrote: Steve, I don't know that a gusset as drawn would do you any good without more I-beam behind it to support it.

Maybe consider this as an alternative?

Willie I don't know if you remember but the wedge fits in a pocket welded into the H beam so as to be removable and replaced with a "+" shaped wedge that would split into 4 pcs in one stroke or even an "X with a vertical line" shape to cut into six pcs.

I agree I should have bought the H-beam 6" longer, but that's water under the bridge.

I figure my triangle, like yours but rotated 180° and tapering down to the bottom of the H-beam should do it.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

(05-30-2013, 09:33 AM)stevec Wrote: Willie I don't know if you remember but the wedge fits in a pocket welded into the H beam so as to be removable and replaced with a "+" shaped wedge that would split into 4 pcs in one stroke or even an "X with a vertical line" shape to cut into six pcs.

I remembered the pocket, but I did forget about the "+" and "X" wedges. Yeah, my idea would definitely be in the way.

Willie

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(05-29-2013, 06:28 PM)stevec Wrote: Well Dave, I split a nice big 16" long 17" diameter log without having to lift it up to the working height I prefer. So, I guess it works GREAT! I have some bugs to work out and changes to make but that's the way I work, design by building.

Steve,

I didn't ask how well does it work?

I was asking How does it work? - mode of operation -What knobs do you twiddle, maybe you could show (with some photos) how the hydraulics do what they do.

DaveH

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

05-30-2013, 05:27 PM

(This post was last modified: 05-30-2013, 05:30 PM by stevec.)

(05-30-2013, 12:05 PM)DaveH Wrote: I was asking How does it work? - mode of operation -What knobs do you twiddle, maybe you could show (with some photos) how the hydraulics do what they do.

DaveH

Well Dave, I wondered if that's what you meant but it was easier for me to give the lame answer I gave.

It takes me forever to do a post with pics that have arrows and letters that I can refer to. I can't even do the arrows as crisp and straight as others can so I'll start with a verbal description.

There is a high pressure pump that is driven by an 8hp engine (I scavenged and rebuilt mine from an old snowblower) feeding 2 valves.

The hydraulic fluid passes through 2 valves in series to be returned through the filter to the tank until one of the valve levers is actuated.

Depending on the valve chosen and which direction it is moved it will either lift the log lifter tray or set it back down. If the other valve is actuated it will either extend the cylinder forcing the log into the wedge until it is split. The other direction retracts the cyl. ready for another log.

A: is the snowblower engine.

B: is the pump

C: is the splitter cylinder

D: is the log lifter cylinder

E: is the splitter valve and

F: is the lifter valve.

1: is the guage showing the pressure at the time of a function (lift, split, return, descend)

2: is the filter on the return line to the tank

3:is the tank/axle/cross frame

4: is the lifter (with tray folded up)

5: is the removable splitting wedge

6 is the backer, now to be reworked

Please ask any further questions that can be answered in one word.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Wow! Nice explanation Steve.

Ed

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Steve,

Thanks, that was a brilliant explanation, and a couple of brilliant photo's as well.

I wondered where the hydraulic pump was (thought it would be much bigger)

A one word answer to a question coming up but the answer must contain at least 3 letters.

Can I have it please?

DaveH

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

05-30-2013, 07:04 PM

(This post was last modified: 05-30-2013, 07:05 PM by stevec.)

Dave, being from Quebec I can reply "Non" Wait til I get the bugs worked out and then we'll talk.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

|