Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

Well Dave, I split a nice big 16" long 17" diameter log without having to lift it up to the working height I prefer. So, I guess it works GREAT! I have some bugs to work out and changes to make but that's the way I work, design by building.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

Well done Steve!!!!!!!!!!

What bent? What you have is pretty similar to what I was planning for the splitter on the processor.

Free advice is worth exactly what you payed for it.

Greg

Posts: 825

Threads: 25

Joined: Jul 2012

Location: N. Bay Ontario

Great splitter project. The older we all get it sure is nice to have a splitter.

sasquatch, proud to be a member of MetalworkingFun since Jul 2012.

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

05-30-2013, 08:00 AM

(This post was last modified: 05-30-2013, 08:02 AM by stevec.)

(05-29-2013, 06:38 PM)f350ca Wrote: What bent?

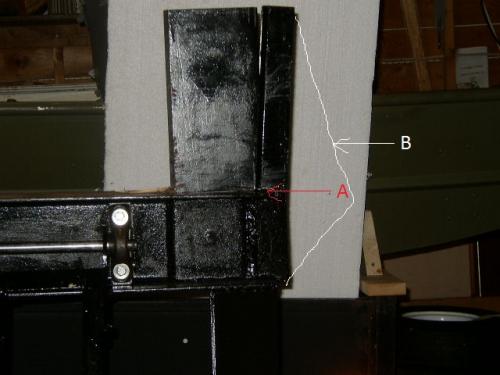

Here's a couple of pics of the bend/tear and potential repair.

In the second pic the red arrow "A" shows the tear at the weak point.

The white triangle "B" shows the possible "gusset" solution. I'll have to remove the wheels and plug the filler neck in order to rotate the machine onto one side then the other as I only do horizontal welds

I was surprised that the wedge had so much rock/tilt in it's "socket".

That's what the backer was supposed to resist.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

Thanks Steve. Guess we should never underestimate the power of hydraulics. For reference what size and height is the backer?

Free advice is worth exactly what you payed for it.

Greg

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)