Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

(02-13-2013, 12:14 PM)Brian Wrote: The screws are 8 BA the smallest on this clock will be 10BA,

Brian.

Brian, so the HIGHER the number the smaller the screw on the BA scale?

(confirms my suspicions that BA stands for "Bloody Awful").

I watch in awe and enjoy your posts.

Steve

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

(02-21-2013, 03:14 PM)stevec Wrote: (02-13-2013, 12:14 PM)Brian Wrote: The screws are 8 BA the smallest on this clock will be 10BA,

Brian.

Brian, so the HIGHER the number the smaller the screw on the BA scale?

(confirms my suspicions that BA stands for "Bloody Awful").

I watch in awe and enjoy your posts.

Steve

Yes Steve I may even sneak in one 12 BA. your hands need to be steady when tapping, so not the thing to do after a night out with the lads.

Glad you enjoy my efforts Brian.

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

(02-13-2013, 12:14 PM)Brian Wrote: Glad you enjoy my efforts Brian.

Brian, I'm ready to bet lots that everyone here does.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 576

Threads: 18

Joined: Feb 2012

Location: Washington State USA

I know Brian has my attention!

Jerry.

ETC57, proud to be a member of MetalworkingFun Forum since Feb 2012.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

I too am watching with interest. Whilst I may never make a clock, there is plenty to learn in this thread that is applicable to machining in general.

Hunting American dentists since 2015.

I for one will never tire of watching your endeavors Brian.

"Billy G"

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Very interesting Brian

DaveH

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

02-25-2013, 03:16 PM

(This post was last modified: 02-25-2013, 03:20 PM by Brian.)

Thanks Lads, now I will have to by a bigger hat.

Just For interest the 12 Ba screw is .048" dia, as small as i want to go!

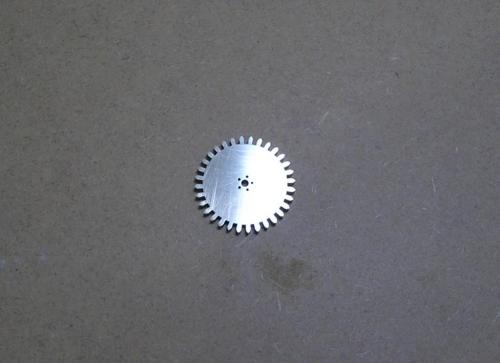

The photo shows a brass 12 Ba holding the tail end of a click spring, The large screw is 8 Ba The spring its self is interesting the finger is made straight, bent to fit the wheel, then hardened by beating it with a hammer to make it springy.

This one is from another clock.

Brian

---You may need to open the file to see it Poor photography???

,

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

02-28-2013, 03:29 PM

(This post was last modified: 02-28-2013, 03:30 PM by Brian.)

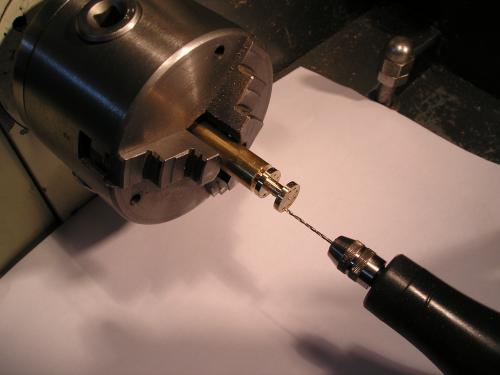

At last the small drill has arrived and I can continue with the pinions. the first is a 5 tooth pinion for the hour wheel reduction

The set up is a mini grinder/ drill clamped to the vertical slide,

Indexing by a 50 t gear at 10 teeth. we get 5 holes to fit pins in for a overhung pinion.

Brian.

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

Now a lantern pinion using the same set up.

The new pinion on test. it works perfectly.

Minimum tooling --maximum satisfaction.

Brian.

---You may need to open the file to see it Poor photography???

---You may need to open the file to see it Poor photography???