09-19-2012, 02:34 PM

Holding small anything can be a nuisance at the best of times. Holding small diameter bars just to cross drill can be even worse.

So to help I made some small V blocks just normal mild steel.

The first part shows NOT the best way to hold a small piece of round bar in a vise.

There is a parallel under the work piece, and the work is held down on to the parallel whilst tightening the vice.

This is not the best way to hold round bar (by a long way).

This is a little better as it is held the full length of the vice jaws. But still not what I would call good.

Here you can see the parallel under the work piece not only giving a little support but also helping to keep it level

Still not particularly good because this can happen, - whooops

So it can be held and drilled like in the above photos however one needs to be careful and mindful of the force applied to the wok piece.

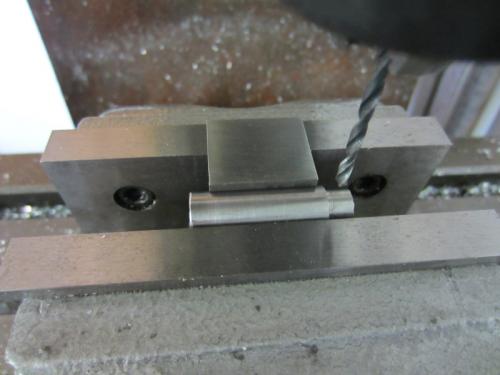

Perhaps a better way is to use some small V blocks.

Now even this set up using a small V block, still isnt a good way to do it. Yep you can really tighten the vice up, but it aint doing your vice much good.

Locate it in the middle of the vice jaws. Much nicer for your vice.

Now this is also a better way, but wouldnt you just know, the work piece is 10mm dia and that is the only 10mm bar left in the whole wide world, no problem use a 10mm drill. (The shank part!)

If it is a long piece fine

Here is the smallest one (of a pair) I have. The same ones as used in the above photos.

It has a cut out that locates on the top side of the vice jaws. Aids to keep everything level and quick to set up.

Here are some photos showing the V blocks in more detail.

Comments are always welcome, good or bad

DaveH

So to help I made some small V blocks just normal mild steel.

The first part shows NOT the best way to hold a small piece of round bar in a vise.

There is a parallel under the work piece, and the work is held down on to the parallel whilst tightening the vice.

This is not the best way to hold round bar (by a long way).

This is a little better as it is held the full length of the vice jaws. But still not what I would call good.

Here you can see the parallel under the work piece not only giving a little support but also helping to keep it level

Still not particularly good because this can happen, - whooops

So it can be held and drilled like in the above photos however one needs to be careful and mindful of the force applied to the wok piece.

Perhaps a better way is to use some small V blocks.

Now even this set up using a small V block, still isnt a good way to do it. Yep you can really tighten the vice up, but it aint doing your vice much good.

Locate it in the middle of the vice jaws. Much nicer for your vice.

Now this is also a better way, but wouldnt you just know, the work piece is 10mm dia and that is the only 10mm bar left in the whole wide world, no problem use a 10mm drill. (The shank part!)

If it is a long piece fine

Here is the smallest one (of a pair) I have. The same ones as used in the above photos.

It has a cut out that locates on the top side of the vice jaws. Aids to keep everything level and quick to set up.

Here are some photos showing the V blocks in more detail.

Comments are always welcome, good or bad

DaveH

, as usual the best ideas are the simplest

, as usual the best ideas are the simplest I could have used them a few times and like the edge that 'sets' them parallel too, Good job

I could have used them a few times and like the edge that 'sets' them parallel too, Good job

, another item on the to do list

, another item on the to do list

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)