Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

(05-26-2013, 06:34 AM)stevec Wrote: Ed, I shoulda known.  I, too, have truble remembering things, aah... what were we discussing? I, too, have truble remembering things, aah... what were we discussing?

Haha - and here I was thinking you were being a smart arse Steve!

Hunting American dentists since 2015.

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

Darren, I think my arse is the smartest thing on me.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 8,854

Threads: 318

Joined: Feb 2012

Location: Arizona/Minnesota

(05-26-2013, 10:29 AM)stevec Wrote: Darren, I think my arse is the smartest thing on me.

Posts: 8,854

Threads: 318

Joined: Feb 2012

Location: Arizona/Minnesota

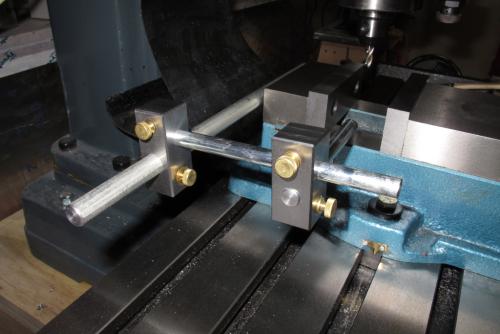

Got'r done!

Well, it's usable anyway. The thumb screws are too small to get a good grip on so I'm going to make some larger heads and press-fit them onto the existing heads.

Ed

Posts: 4,452

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

Looks good Ed!

Willie

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Looks very nice Ed

DaveH

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

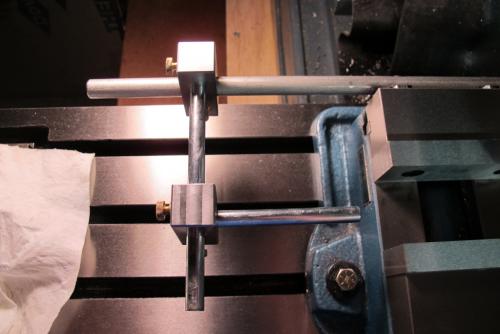

made this screw today, its for a puller that I am making the taper on it will cause the jaws to close on what you are pulling off. it still has to be trimmed to length after I get the cross bar made.

![[Image: 2013-05-27145547.jpg]](http://i1222.photobucket.com/albums/dd484/Superdave257/2013-05-27145547.jpg)

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 1,459

Threads: 159

Joined: Feb 2012

Location: Northern England

(05-26-2013, 01:11 PM)EdK Wrote: Got'r done!

Well, it's usable anyway. The thumb screws are too small to get a good grip on so I'm going to make some larger heads and press-fit them onto the existing heads.

Ed

You will wonder how you managed without it now

John

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

05-27-2013, 04:16 PM

(This post was last modified: 05-27-2013, 04:19 PM by stevec.)

Dallen, I had to look for the "taper" , I found it on the threaded side of the knurled "knob".

As far as I can see it's going to be a puller of very distinct length. I have a couple of pullers that use the taper idea to close the jaws but the pressure screw threads into the tapered "jaw tightening " screw.

I notice a hole in the end of your screw, will that be for the puller (pressure) screw or just for a pointed "pilot" center?

I'm going to the shop right now to check on my feeble , beer addled mind.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

yes the pressure screw will fit into the hole you see in the end, only it will screw in from the knob side. I am making it to use on clock movement so I doesn't have to be very big. its primary use will be to remove the hand from the center shaft of the movement.

I saw one on ebay and figured that I needed one without the cost and that I could make it better looking. It will be a couple days before I do anything else as I have my mill tired up with a part that I don't want to have to redo the setup on and can't finish it till I go to town and hopefully find a carbide drill or endmill the right diameter to cut thru the casehardening.

Any way it was fun to make and its was something that the doctors wouldn't get to po'ed at me about after having a heart attack on monday, don't want to mess up the stint that they put in.

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

|

I, too, have truble remembering things, aah... what were we discussing?

![[Image: 2013-05-27145547.jpg]](http://i1222.photobucket.com/albums/dd484/Superdave257/2013-05-27145547.jpg)