Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

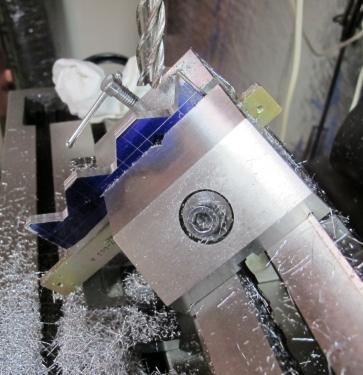

The check valve quit checking in a friends compressor. Tore it apart and found a plastic spool broken. Thought about making the new one out of brass but was afraid it might not seal on the flat valve seat so machined one out of an old screw driver handle. The air out of those little compressors must get some hot. The black blob is the first try, made the next one out of brass and it worked like a charm.

![[Image: IMG_0268.jpg]](https://lh6.googleusercontent.com/-wF04qIDd39A/UIXUGPvsonI/AAAAAAAAAp0/opJ-XMWT4yI/s1600/IMG_0268.jpg)

Free advice is worth exactly what you payed for it.

Greg

Posts: 825

Threads: 25

Joined: Jul 2012

Location: N. Bay Ontario

Interesting project Greg, and my compressor head does get quite hot. (No wonder the tanks get condensation in them.)

sasquatch, proud to be a member of MetalworkingFun since Jul 2012.

Posts: 825

Threads: 25

Joined: Jul 2012

Location: N. Bay Ontario

Back at cleaning out my deceased friends shop/garage, found a Rusty #7 M/T Live center for a tail stock. After soaking it in penetrating fluid, finally got the lock ring off to see why it wouldn't turn, the radial bearing in it was severely chewed up.Must of had a half pound of cuttings inside it.

So, will keep it as a conversation piece or maybe someday it could be fitted into a piece of metal art.

Picked up the Logan Shaper today and have it back home.

Also bought his new set of Popular Mechanics "Shop Tips" (Reprints,) 26 volumes from 1905 to 1930, and also the index to the same. Also a 1944 issue of "How to run a lathe" from South Bend.

Oh,, and also found a small "Boston Gear" reducer, 18-1 ratio it appears.

sasquatch, proud to be a member of MetalworkingFun since Jul 2012.

Posts: 537

Threads: 15

Joined: Jun 2012

Location: Cambridge, England

(10-22-2012, 06:24 PM)f350ca Wrote: The check valve quit checking in a friends compressor. Tore it apart and found a plastic spool broken. Thought about making the new one out of brass but was afraid it might not seal on the flat valve seat so machined one out of an old screw driver handle. The air out of those little compressors must get some hot. The black blob is the first try, made the next one out of brass and it worked like a charm.

Compressing air does generate a whole load of heat, think about diesel engines for a second, it takes only a 15:1 compression ratio at 350RPM to start auto igniting diesel.

so a plastic seal doesn't have a chance, most plastics have lost all integrity by the time they pass 130 degrees C, in fact I cant think of any that have any integrity at all by 120 degrees.

And Dave H sorry I didn't get a notification on this thread so didn't know you'd posted your welding effort,

As others have said,

More cleaning first and then knowing that you used stick, I will ask; have you removed all the slag? as it does look like you have a shielding problem, if you could post what settings you used and the welding rod details, so anything written on the side of the welding rod package, by the look of the flux I would guess 6013 rods or similar, but the rod wire diameter is also important.

Regards

Rick

Whatever it is, do it today, Tomorrow may not be an option and regret outlasts fatigue.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(10-23-2012, 05:52 AM)Rickabilly Wrote: And Dave H sorry I didn't get a notification on this thread so didn't know you'd posted your welding effort,

As others have said,

More cleaning first and then knowing that you used stick, I will ask; have you removed all the slag? as it does look like you have a shielding problem, if you could post what settings you used and the welding rod details, so anything written on the side of the welding rod package, by the look of the flux I would guess 6013 rods or similar, but the rod wire diameter is also important.

Regards

Rick

It's fine Rick, at my next attempt I will make a note of everything.

DaveH

Posts: 537

Threads: 15

Joined: Jun 2012

Location: Cambridge, England

(10-15-2012, 04:51 AM)Mayhem Wrote: Really glad to see you have been able to get into the shop Rick. Let's hope the back continues to play nice.

Just out of interest (I know there will be a build thread) but what are the chains for?

Unfortunately I've been out of commission since, I'm getting pretty sick of the discovery channel

The chains keep the flame inside the box, they prevent sparks flying out as well, but the main purpose is to provide a stable laminar region to create an efficient flame and to prevent a slight breeze pushing all the heat right out one end of the tunnel.

Regards

Rick

Whatever it is, do it today, Tomorrow may not be an option and regret outlasts fatigue.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

10-27-2012, 09:29 AM

(This post was last modified: 10-27-2012, 09:31 AM by Mayhem.)

Sorry to hear that Rick.

Did some welding today and it was a bit fiddly and I could have used a 3rd hand, so I made one. All made from bits from the scrap box and I will make a few more of different sizes. I think they have other names as well, such as lazy birds but I've always heard of them as 3rd hands.

Of course, I didn't think to take pictures when I was actually using it, so here are a few staged shots, for those of you who may not be familiar with these.

Very handy for this type of work.

Hunting American dentists since 2015.

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

Thanks A Lot, now I have another project. Never seen one before, they look real handy.

Free advice is worth exactly what you payed for it.

Greg

Posts: 8,860

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

I worked on Koama's wiper support plates. I got the tedious part done, the 'V' section. The rest should go quick, famous last words.

Ed

Posts: 4,461

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

10-27-2012, 12:37 PM

(This post was last modified: 10-27-2012, 12:42 PM by Highpower.)

Darren, that reminds me...... I need to go through my scrap bucket and make a couple of those myself. I bought some aluminum bronze filler rod a year ago to help get a better ground on them after seeing Jody's mod that he did on his. Another one of those "I'll get to it someday" projects.

Last week I fought with some old stick electrodes that have been sitting in a drawer for quite awhile. They simply vaporized when I tried to weld with them, and I had to run to the local hardware to pick up some fresh rods. Well, they weren't so 'fresh' either.

I finally broke down and ordered a rod oven in the hopes that I can salvage the electrodes that I have. I think the manufacturers should be required to sell vacuum sealed "six-packs" of stick welding rods.

Willie

|

![[Image: IMG_0268.jpg]](https://lh6.googleusercontent.com/-wF04qIDd39A/UIXUGPvsonI/AAAAAAAAAp0/opJ-XMWT4yI/s1600/IMG_0268.jpg)

![[Image: IMG_0268.jpg]](https://lh6.googleusercontent.com/-wF04qIDd39A/UIXUGPvsonI/AAAAAAAAAp0/opJ-XMWT4yI/s1600/IMG_0268.jpg)