(05-31-2015, 09:00 PM)PixMan Wrote: (05-31-2015, 11:24 AM)RobWilson. Wrote: Hi Lads

Just finished knocking up a couple of ramps to use at work , 3 ft x 1 ft x 6" made from a wee bit of 1/8 plate .

<deleted photos>

Good for 50 ton the pair

Rob

Rob,

Those are seriously nice ramps! How much do they weigh?

Will they be in a rather permanent location? If not, would they need handles or slots to aid in having a lift point?

Very odd . I was asked the very same thing on madmodder.

About 15kg each .not heavy .and yes they are not in a fixed location .

So why do you think they would need handles and where would you place said handles Ken ?

What I fined odd is why folk would think that they would need handles .if one came across a 3ft log would you be unable to pick it up due to the lack of handles ?

Or is it that folk think I can't design a set of ramps ? And have missed something .

Maybe it's just that there is no need for any handles/slots .becouse if I had felt the need for such I would have added such things .

Look at the underside how many places dose one need yo get hold of something?

Rob,,,,,,,,,it's getting old

Posts: 642

Threads: 14

Joined: Oct 2013

Location: East Sussex, UK

(06-01-2015, 02:11 AM)RobWilson. Wrote: (05-31-2015, 09:00 PM)PixMan Wrote: (05-31-2015, 11:24 AM)RobWilson. Wrote: Hi Lads

Just finished knocking up a couple of ramps to use at work , 3 ft x 1 ft x 6" made from a wee bit of 1/8 plate .

<deleted photos>

Good for 50 ton the pair

Rob

Rob,

Those are seriously nice ramps! How much do they weigh?

Will they be in a rather permanent location? If not, would they need handles or slots to aid in having a lift point?

Very odd . I was asked the very same thing on madmodder.

About 15kg each .not heavy .and yes they are not in a fixed location .

So why do you think they would need handles and where would you place said handles Ken ?

What I fined odd is why folk would think that they would need handles .if one came across a 3ft log would you be unable to pick it up due to the lack of handles ?

Or is it that folk think I can't design a set of ramps ? And have missed something .

Maybe it's just that there is no need for any handles/slots .becouse if I had felt the need for such I would have added such things .

Look at the underside how many places dose one need yo get hold of something?

Rob,,,,,,,,,it's getting old

Rob,

As you know it was I that made the comment on Madmodder: It's not the weight it's the gripability. If it were a log your hands curl round it's curves and you can lift it. When those ramps are on a flat surface there is nothing to grip, so you can't flip it to be able to use the underside bits to hold.

... it's the defence strategy a tortoise has evolved

Andrew Mawson, proud to be a member of MetalworkingFun Forum since Oct 2013.

aye right .it to much effort to flip one over Andrew .

Rob

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 1 user Likes Mayhem's post:

EdK (06-01-2015)

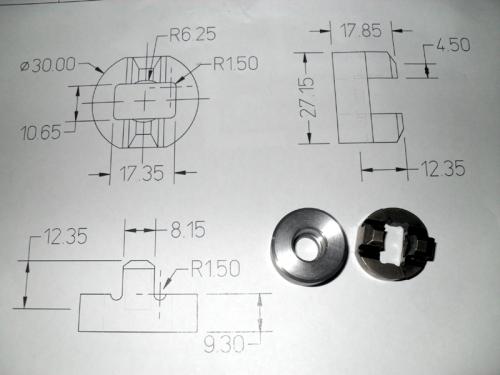

Managed to get around to making the drive adapter for the vacuum pump on my Mum's car. I need to get a start on putting it back together next weekend. She has been given a car to loan from her step-sister, which is good as I have been busy with other things...

Machined blank next to the broken part:

Finished part. Ignore the errant hole, I obviously forgot to carry the 1 when counting the dials  The chamfers will get done with a file, as I couldn't be bothered trying to grab it in the vise at an angle. They are not critical and certainly don't need to be so big:

Hunting American dentists since 2015.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

(05-31-2015, 11:05 PM)TomG Wrote: I used a .376 reamer David. Don't know exactly what the fit is, but it feels pretty good.

Tom

first one I did I checked the selector and found that it was like 4 thousands under what the hole was suppose to be, so I always measure the selector then ream the hole for a slip fit. Another place to watch out for is the detent pin hole for the selector, don't know if its a problem with the measurement on the print I used or with the casting but had one selector that ended up with a bunch of sideways slop which I didn't like.

DA

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

Rob,

Please don't take offense. I just thought it would be nice to have a slot hole in the sides to enable quick pick-up or repositioning because my impression in looking at the robust construction and weight-bearing rating of them was that they would be 4 times the 15kg weight you say they are.

No worries. Sorry.

Ken

RobWilson

Unregistered

The following 1 user Likes RobWilson's post:

EdK (06-01-2015)

Hi Ken ,,,,,,,,,no worries, no offence taken mate ,,,,,,,,,,some days I just speak whats on my mined

I did think of all the angles / pros and cons when I made them , as they have to deal with a very wide variety of wheel types/sizes/material and loads from a few Kgs to several thousand Kgs .

So no slots/ holes in the top deck . cutting holes in the sides well they could only go at the thick end of the wedge , that puts them in a place that would make them ok for a vertical lift from the floor ,but nothing else ,or unless your Andrew and cant get a grip to turn a wee ramp on edge  . The holes/slots in that position would be useless for carrying the ramps around ,much better to carry them vertically by the strategically placed cross member,easier to carry them vertically by the thin end as the stand up fine on the fat end , so no point having a slot on that face . So that ruled side / end slots out .

As for any type of sticky out handle well that would probably just get hung up on gear in the back of the van .

I used them today with no problems on a couple of sites with different types of machine , so I will have them independently tested for insurance purposes tomorrow .

Cheers Rob

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 1 user Likes Mayhem's post:

EdK (06-01-2015)

(06-01-2015, 09:37 AM)RobWilson. Wrote: ...some days I just speak whats on my mined  ... ...

I think that is referred to as lousy impulse control  It catches me out sometimes as well.

Just recently a colleague asked if I was suffering from late onset tourett's syndrome. I told them where to go but they said that only illustrated their point...

Hunting American dentists since 2015.

Posts: 642

Threads: 14

Joined: Oct 2013

Location: East Sussex, UK

The following 1 user Likes awemawson's post:

PixMan (06-01-2015)

It's alright Ken, Rob's just a bluff Northerner (like me!) - he means no harm

I suppose you can always jam a shovel under a corner to start a lift - I'd envisioned a short D shaped cut out in one side at ground level to put a couple of fingers in.

Andrew Mawson, proud to be a member of MetalworkingFun Forum since Oct 2013.

(06-01-2015, 11:13 AM)awemawson Wrote: It's alright Ken, Rob's just a bluff Northerner (like me!) - he means no harm

Errrrrrrrr Northerner Andrew  ,,,,,,,,,,,,,,,,,,,,,,,,,, thought you were a Southern Softy  ,,,,,,,,,, with soft hands  remember I live on the good side of Hadrian s wall .

Rob

|

The chamfers will get done with a file, as I couldn't be bothered trying to grab it in the vise at an angle. They are not critical and certainly don't need to be so big:

The chamfers will get done with a file, as I couldn't be bothered trying to grab it in the vise at an angle. They are not critical and certainly don't need to be so big:

,,,,,,,,,,,,,,,,,,,,,,,,,, thought you were a Southern Softy

,,,,,,,,,,,,,,,,,,,,,,,,,, thought you were a Southern Softy