02-19-2012, 06:36 PM

Just testing to see if I can upload attachments properly...

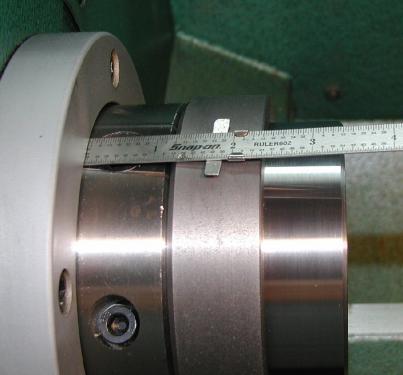

I wanted to put together a spider for the business end of my lathe spindle. I have a 21 inch barrel blank I need to fit and chamber, which poses a problem because the distance between the ends of the jaws on my 4-jaw chuck and my outboard spider screws is 22 inches. :(

I cut down a 6 inch D1-4 back plate and counter-bored the front end to hold a piece of 4" steel pipe with a 1 inch wall thickness. Hopefully that will be enough to prevent any flex in use. Then drilled and tapped for the brass tipped set screws to dial in the bore. I may have to make up some larger brass cups for the set screws though, to get a better purchase on the work. :dodgy:

The new spider reduces the length between them to 19 inches which is good for me. I also won't have to worry about crashing into the massive jaws on that 8" 4-jaw chuck.

At least that's the plan....

I wanted to put together a spider for the business end of my lathe spindle. I have a 21 inch barrel blank I need to fit and chamber, which poses a problem because the distance between the ends of the jaws on my 4-jaw chuck and my outboard spider screws is 22 inches. :(

I cut down a 6 inch D1-4 back plate and counter-bored the front end to hold a piece of 4" steel pipe with a 1 inch wall thickness. Hopefully that will be enough to prevent any flex in use. Then drilled and tapped for the brass tipped set screws to dial in the bore. I may have to make up some larger brass cups for the set screws though, to get a better purchase on the work. :dodgy:

The new spider reduces the length between them to 19 inches which is good for me. I also won't have to worry about crashing into the massive jaws on that 8" 4-jaw chuck.

At least that's the plan....

Willie