Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 3 users Like EdK's post:

Vinny (05-22-2023), arvidj (05-22-2023), JScott (05-22-2023)

After too much time I finally found the bug in my deceleration code. An "if" statement inside of an "if" statement that should have been outside of the first statement. I'm a bit rusty at coding. Use it or lose it, that's what happened.

It's working like a champ now. I'll test it on the mill tomorrow.

Ed

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 3 users Like EdK's post:

Vinny (05-26-2023), JScott (05-27-2023), Highpower (05-27-2023)

I finally got around to trying it on the mill. Lots of torque, couldn't even slow it down by pushing against the table. Way too slow for a rapid traverse though. I think I'll look for a motor that's 200 - 250 RPMs. The one I have now will work for raising and lowering the head so it wasn't a wasted purchase.

Ed

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

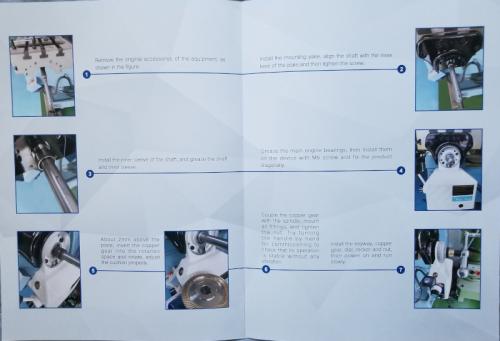

After looking around for a new motor and calculating what it would cost I decided it would be cheaper and quicker to just order a normal x axis power feed that's sold for a Bridgeport style mill. It should not be a lot of work to adapt it to my mill. At least that's the theory.

Ed

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

The following 4 users Like Highpower's post:

JScott (05-31-2023), f350ca (05-31-2023), EdK (05-31-2023), Vinny (05-31-2023)

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Got the power feed today. Now to take a lot of measurements to see if this will actually work on my mill, with mods of course.

Ed

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

I stumbled upon a 220RPM motor that had the same mounting as the 100RPM motor that I originally tried on the X axis. It claimed to have 30n-m of torque vs 3n-m on the 100RPM. So I bought one thinking it should be perfect and I could use all of the work I put into the 100RPM motor on this one.

I tested it out on the mill today and what a joke! It had less torque than the 100RPM motor has.

The standard X axis mill power feeds run at about 200RPM so this motor should have given me plenty of torque and a decent rapid movement speed. It's going back to Amazon.

Back to figuring out how to mount the Vevor power feed.

Ed

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

(12-18-2023, 02:58 PM)EdK Wrote: I stumbled upon a 220RPM motor that had the same mounting as the 100RPM motor that I originally tried on the X axis. It claimed to have 30n-m of torque vs 3n-m on the 100RPM. So I bought one thinking it should be perfect and I could use all of the work I put into the 100RPM motor on this one.

I tested it out on the mill today and what a joke! It had less torque than the 100RPM motor has.

Ed

If it sounds too good to be true...

Willie

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(12-18-2023, 05:03 PM)Highpower Wrote: (12-18-2023, 02:58 PM)EdK Wrote: I stumbled upon a 220RPM motor that had the same mounting as the 100RPM motor that I originally tried on the X axis. It claimed to have 30n-m of torque vs 3n-m on the 100RPM. So I bought one thinking it should be perfect and I could use all of the work I put into the 100RPM motor on this one.

I tested it out on the mill today and what a joke! It had less torque than the 100RPM motor has.

Ed

If it sounds too good to be true...

Yea, I bought one and am sending it back because it sounded like it was going to fall apart. The second one was a bit quieter so I gave it a shot not expecting much. They're both heading back to Amazon.

Ed