Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 1 user Likes Mayhem's post:

Vinny (01-23-2022)

Perhaps the Ultra High and High refer not to the accuracy of the vice but rather the manufacturing process...

Hunting American dentists since 2015.

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Here's Precision Matthews reply.

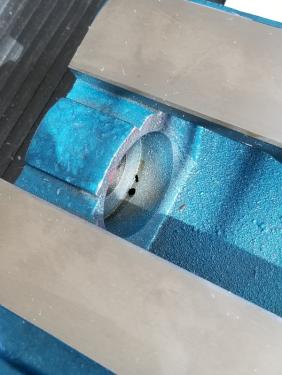

"Those voids are going to happen, and yes I see them in vises like this a lot. That will not hurt anything, but I will note that if anything is ever caused by that void, we will cover it.

The threads should be OK, I do not see that they look like trapezoidal threads, most larger threads like that seem to have a flat on them that you are seeing. Make sure it works and feels OK, but that looks pretty normal to me, I just checked the part I have in stock with the same threads and it looks the same.

As you can see with the vise you have from before, there is a difference in them, but you should be fine with this one, it will work just as it should.

You can always return it if you do not like it, that's not a problem. We do also have the HAV-4 in stock if you want something along the lines of what you had before."

I'll keep it and use it as is as long as they're willing to replace it should it fail.

Ed

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

(01-24-2022, 12:29 PM)EdK Wrote: Here's Precision Matthews reply.

"Those voids are going to happen, and yes I see them in vises like this a lot.

Ed

Well that certainly instills confidence in a product doesn't it?

I sure would hang onto a copy of that reply though to refresh their memory if needed.

Willie

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

Highpower (01-25-2022)

(01-24-2022, 08:08 PM)Highpower Wrote: I sure would hang onto a copy of that reply though to refresh their memory if needed.

They sent me a PDF of the receipt and they had put a note on it about the void and the fact that they would replace the vise if the vise broke because of the void. So I think I'm safe. Matt has a pretty good reputation for customer service.

Ed

Posts: 794

Threads: 52

Joined: Mar 2012

Location: Rochester, NY

01-25-2022, 08:07 AM

(This post was last modified: 01-25-2022, 08:09 AM by rleete.)

I really can't see that void being much of an issue. Maybe grease would seep out, but I can't imagine it would break. I'd have to check mine, but I don't remember if there's a hole there or not. I do know mine has a tiny grease fitting on top of that pocket. The bearings, while smooth after cleaning, were full of gunk, as were the threads.

The spherical pocket may cause a little roughness, but I had the same issue with my grinding vise, and just used a hand drill and a ball end mill to make a more defined pocket. It's held up well under pretty rough use for years.

I've had mine for a few years, and I can't remember the seller, but I believe it was eBay.

Full of ideas, but slow to produce parts

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(01-25-2022, 08:07 AM)rleete Wrote: The spherical pocket may cause a little roughness, but I had the same issue with my grinding vise, and just used a hand drill and a ball end mill to make a more defined pocket.

I plan on doing something similar with a die grinder and ball shaped cutter.

Ed

Posts: 205

Threads: 3

Joined: Jul 2014

Location: Vermont

Those are blow holes. Too wet moulding sand, poor porosity, and/or too low metal temp. Ask me how I know......