01-16-2022, 02:44 PM

My trusty old Craftsman drill press never had the crank to raise and lower the table. It wasn't available when dad bought the thing in the 1970's. Searches for one have proved fruitless, and my back has seen better days. So, when all else fails, reinvent the wheel!

I used a cheap-o Chinese (redundant, I know) power supply and linear actuator found on the web. Walmart, I believe. Switch boxes and switch were leftovers I had from Radio shack (man, I miss that place) combined with Home Depot wiring and connectors. Power is wired through the integral lamp in the head, so power supply isn't on except when using the thing. Button is momentary in both directions, and linear actuator has integral stop/limit switches.

Pictures of the setup. Please excuse the mess.

Botton mount:

Top mount (underside of table):

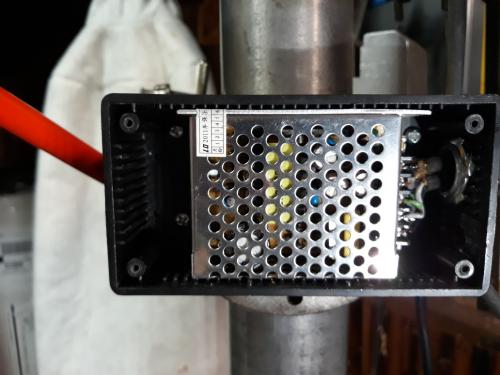

Power supply, mounted on table where original crank was supposed to go:

Finally, the switch, mounted to the back of the head casting:

It's not the quickest way to get the table up and down, but it works quite well, and saves me from trying to lift the damn thing by hand.

I used a cheap-o Chinese (redundant, I know) power supply and linear actuator found on the web. Walmart, I believe. Switch boxes and switch were leftovers I had from Radio shack (man, I miss that place) combined with Home Depot wiring and connectors. Power is wired through the integral lamp in the head, so power supply isn't on except when using the thing. Button is momentary in both directions, and linear actuator has integral stop/limit switches.

Pictures of the setup. Please excuse the mess.

Botton mount:

Top mount (underside of table):

Power supply, mounted on table where original crank was supposed to go:

Finally, the switch, mounted to the back of the head casting:

It's not the quickest way to get the table up and down, but it works quite well, and saves me from trying to lift the damn thing by hand.

Full of ideas, but slow to produce parts