12-28-2021, 06:50 PM

In the latest delivery thread I just posted some pictures of the tools I found at the local big box store here in Colombia (see last attachment below). The store is just over an hour drive away. (Driving in Colombia is a whole, separate thread!) Got this drill press for the usual price for a 5 speed, Chinese, bench top model. I probably don't really, really need a drill press but they are so handy and useful I just like having one around. Since I'm retired I have more time to play around and this is going in my little shop. I'm going to add items here and there as I find them. Things like a bench grinder, bench vise, band saw, etc.

Now to get down to it. I've been going through the old, back issues of Popular Mechanics from the late 40's and on up to the mid 50's so far. I've done this before and really was amazed by the explosion of home workshop information that was fueled by the after effect of WWII. It seems like everybody had some kind of home shop going on in their garage, basement or wherever. They were working in wood, metal, glass, everything under the sun. Building furniture, lamps, photography gadgets, you name it. There are plans to make anything and everything including the machine tools such as drills, scroll saws, table saws, die filers etc. It also seems like many, many folks had a small lathe as well.

One of the things that is mentioned quite often is light milling with a drill press. This would be a great feature for a drill press which brings me to the point of this thread. The drill presses in use back then had the chuck mounted to the spindle/quill with a mechanical fastener such as a machine screw or bolt. This allowed the drill to accept the side load imparted by the cutting action of an endmill say when facing or cutting a slot. Today's drill press has the chuck mounted on a tapered nose so when any side load is added you better watch where you're standing because the chuck is going to leave rapidly. All this is old news. But........

All this is old news. But........

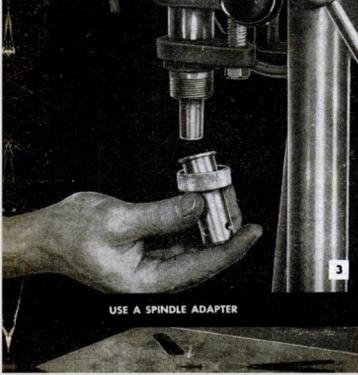

Going through the old articles (you guessed it) there was one on milling with a drill press. And this caught my eye.

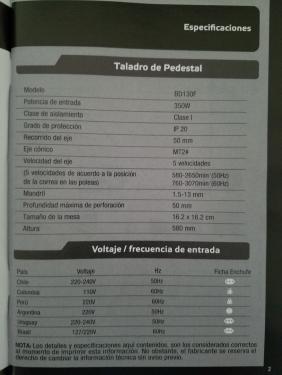

It's a little gem called a spindle adapter; which you can mount if your drill press doesn't have a mechanical connector for the chuck. This one is apparently attached with a threaded collar. So......., I thought to myself, why not add a spindle adapter to this drill press. Voila, light milling here we come! Here is the data on my drill press and if my Spanish is up to the task it appears to have an MT2 taper on the spindle nose. The nose isn't threaded but it could be drilled and tapped to hold the adapter with a screw like the chuck on a hand drill is mounted.

(Note: this manual is in Spanish and Portugese; very handy)

I started digging for a spindle adapter for female MT2 going to a 1/2" bore. No luck; on any size. Well, if you can't get one...., make one (thanks Hawkeye). After more digging I have come up with an idea to use a straight shank ER collet chuck reamed to an MT2 taper. This would provide a stout attachment method and the ability to mount small end mills or a tiny fly cutter.

These ER collet chucks come in various diameters of straight shanks. I just need to select one with enough "meat" and Bob's your uncle. The chuck will be held to the spindle by a socket head capscrew of sufficient diameter, say, 3/8" or 10 mm. From where I sit I think a C25 or C32 (25mm or 32mm shank) with a 10mm bore would be a good starting point. They come in shaft lengths from 50mm up to 200mm. I think 50 might be little short but cutting down a longer one to keep it shorter and more rigid is doable.

Well, there it is. Maybe there is already something readily available out there and any info anyone can provide would be appreciated.

So, I'm looking for input and ideas before I start ordering parts and pieces. I need to find out more about the dimensions inside the collet chuck to see if there is room for a socket head cap screw and if there is enough material to provide a shoulder for the screw head, etc.

Thanks for listening and more to come.

JScott

Now to get down to it. I've been going through the old, back issues of Popular Mechanics from the late 40's and on up to the mid 50's so far. I've done this before and really was amazed by the explosion of home workshop information that was fueled by the after effect of WWII. It seems like everybody had some kind of home shop going on in their garage, basement or wherever. They were working in wood, metal, glass, everything under the sun. Building furniture, lamps, photography gadgets, you name it. There are plans to make anything and everything including the machine tools such as drills, scroll saws, table saws, die filers etc. It also seems like many, many folks had a small lathe as well.

One of the things that is mentioned quite often is light milling with a drill press. This would be a great feature for a drill press which brings me to the point of this thread. The drill presses in use back then had the chuck mounted to the spindle/quill with a mechanical fastener such as a machine screw or bolt. This allowed the drill to accept the side load imparted by the cutting action of an endmill say when facing or cutting a slot. Today's drill press has the chuck mounted on a tapered nose so when any side load is added you better watch where you're standing because the chuck is going to leave rapidly.

All this is old news. But........

All this is old news. But........Going through the old articles (you guessed it) there was one on milling with a drill press. And this caught my eye.

It's a little gem called a spindle adapter; which you can mount if your drill press doesn't have a mechanical connector for the chuck. This one is apparently attached with a threaded collar. So......., I thought to myself, why not add a spindle adapter to this drill press. Voila, light milling here we come! Here is the data on my drill press and if my Spanish is up to the task it appears to have an MT2 taper on the spindle nose. The nose isn't threaded but it could be drilled and tapped to hold the adapter with a screw like the chuck on a hand drill is mounted.

(Note: this manual is in Spanish and Portugese; very handy)

I started digging for a spindle adapter for female MT2 going to a 1/2" bore. No luck; on any size. Well, if you can't get one...., make one (thanks Hawkeye). After more digging I have come up with an idea to use a straight shank ER collet chuck reamed to an MT2 taper. This would provide a stout attachment method and the ability to mount small end mills or a tiny fly cutter.

These ER collet chucks come in various diameters of straight shanks. I just need to select one with enough "meat" and Bob's your uncle. The chuck will be held to the spindle by a socket head capscrew of sufficient diameter, say, 3/8" or 10 mm. From where I sit I think a C25 or C32 (25mm or 32mm shank) with a 10mm bore would be a good starting point. They come in shaft lengths from 50mm up to 200mm. I think 50 might be little short but cutting down a longer one to keep it shorter and more rigid is doable.

Well, there it is. Maybe there is already something readily available out there and any info anyone can provide would be appreciated.

So, I'm looking for input and ideas before I start ordering parts and pieces. I need to find out more about the dimensions inside the collet chuck to see if there is room for a socket head cap screw and if there is enough material to provide a shoulder for the screw head, etc.

Thanks for listening and more to come.

JScott

JScott, proud to be a member of MetalworkingFun Forum since Mar 2014.