05-20-2021, 03:20 PM

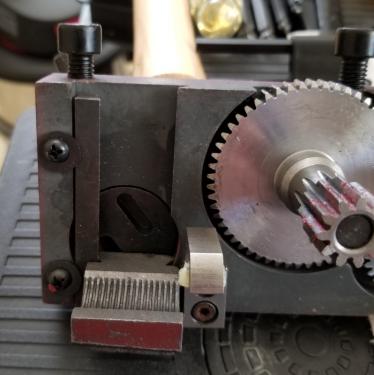

They sure cheaped out on the half nuts. I only got half a half nut. That aluminum steel bracket to the right of the half-half nut supports the top side of the lead screw when the half-half nut is engaged. That's certainly not going to last very long getting chewed up by the lead screw.

You can see the slot is there in the disk for adding the missing half-half nut. I'll add that to my LittleMachineShop order. Not in stock at the moment.

Ed

EDIT: the bracket is steel, not aluminum.

You can see the slot is there in the disk for adding the missing half-half nut. I'll add that to my LittleMachineShop order. Not in stock at the moment.

Ed

EDIT: the bracket is steel, not aluminum.