I had to remove a wood constructed bench to make room for my new mill and ever since I have missed the work space and storage. I decided to build a smaller bench in the same spot but I would make it out of metal rather than the 2x4 construction of the old bench. Here is the old bench.

This is the space I have to work with now after moving the parts washer.

The bench will be 4' long, 36" tall and 2' deep with a lower shelf. I have some left over 3/4" melamine that I will use for the top and shelf. The first job was to cut some 1 1/2" square tubing to length using the band saw. Here is the start.

I setup the end sections first.

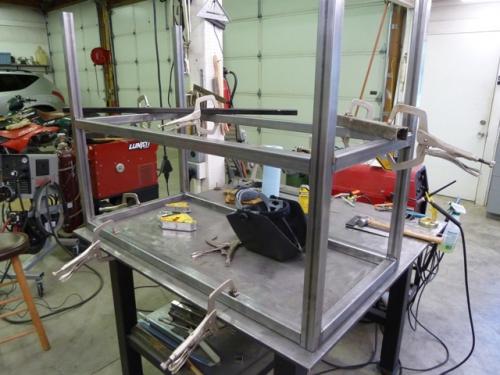

Lots of clamps help and also having a good table. When I get it square I tack all of the tubes.

I flip the weldment over and clamp to the table and finish tacking the tubes. Next I weld out the joints. Here is the first end piece welded up.

After finishing the other end piece I set them up on the table using the long tubes to set the length and squared it up. After tacking the top section I added the lower cross tubes that will support the shelf.

Once everthing was tacked I started welding all of the joints. I like to weld in position if possible so I flip the weldment around as needed. Here are some closeups of the welds. I am only showing the decent ones.

I wanted to add leveling feet so i cut some 1/4" thick flat bar to length that I will weld into the tubing.

This is the space I have to work with now after moving the parts washer.

The bench will be 4' long, 36" tall and 2' deep with a lower shelf. I have some left over 3/4" melamine that I will use for the top and shelf. The first job was to cut some 1 1/2" square tubing to length using the band saw. Here is the start.

I setup the end sections first.

Lots of clamps help and also having a good table. When I get it square I tack all of the tubes.

I flip the weldment over and clamp to the table and finish tacking the tubes. Next I weld out the joints. Here is the first end piece welded up.

After finishing the other end piece I set them up on the table using the long tubes to set the length and squared it up. After tacking the top section I added the lower cross tubes that will support the shelf.

Once everthing was tacked I started welding all of the joints. I like to weld in position if possible so I flip the weldment around as needed. Here are some closeups of the welds. I am only showing the decent ones.

I wanted to add leveling feet so i cut some 1/4" thick flat bar to length that I will weld into the tubing.

Collecting tools for 30 years.