12-29-2017, 12:38 AM

I got my Christmas present from the Mrs. early this year thanks to a Black Friday deal.

It's an AmScope stereo microscope that will for the most part, replace my headband magnifier and $15 plastic USB "microscope".

![[Image: 41yMfdtRGtL._SX522_.jpg]](https://images-na.ssl-images-amazon.com/images/I/41yMfdtRGtL._SX522_.jpg)

Unfortunately being an import from China it has a lot of the typical problems right out of the box. First and foremost are the two sliding support rods for the adjustable boom stand. The center support houses some 20mm linear ball bearing sleeves for the upper rod to ride on while sliding back and forth which is great compared to plain bushings. However the manufacturer uses undersized soft steel rods which have a thin chrome flashing applied. Being undersized the rods wobble a bit in the bores. Even worse is that after only a few times sliding back and forth through the hard ball bearing sleeves the chrome on the rod start to compress and begin fretting - making crunchy, crunchy noises and dragging. So the two original rods were the first things to go. I turned two new rods from some properly hardened linear shafting which is a full 20mm OD. Butter smooth operation now.

You can make out some of the fretting in the center of the original shaft below.

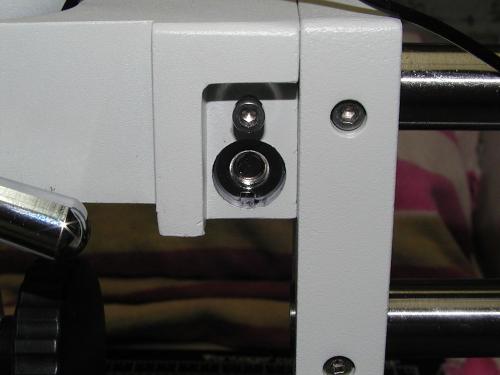

The other issues are somewhat familiar to a lot of us I'm sure. Chinese hardware and attention to detail. The fasteners are also undersized and flash chromed. The socket head cap screws wobble in their threaded holes and the hex sockets are sloppy and deformed. I've replaced them with quality stainless steel fasteners. Same for thumb screws.

The focus rack that holds the microscope head to the boom stand rotates on the upper shaft of the boom stand to allow adjustment of the head in that axis. It is locked in position by tightening a lever much like the quill lock on a vertical mill. Two tapered cotters are squeezed together against the shaft to hold it in place. Mine would not even tighten up much less lock in place. I found the cotters were twisted in the bore and only a knife edge of the tapers were contacting the shaft. The shoulder bolt that runs through the cotters was hitting the screws that guide them in the bore. This prevented the cotters from getting pushed far enough into the bore to contact the shaft fully.

I had to re-drill and tap two new holes in the bottom of the focus rack on the center line of the bore for the guide screws and move them in more to allow the shoulder bolt to fully tighten on them.

I also had to re-drill (straight and perpendicular to the shaft center) and install a Helicoil insert for the SHCS that secures the focus rack to the shaft to keep it from pulling off when the lock lever is loosened. The original hole was sloppily drilled and threaded at a 10-15° downward angle, leaving such a loose thread fit that I could almost pull the screw straight out without turning it.

I still need to make an adapter to better secure the camera to the trinocular port. The camera lens just slides down into the port and sits there. The slightest movement of the scope head or USB cable will spin the camera (and your view on a monitor). Ain't nobody got time for that. Hopefully soon I'll be able to begin using it instead of fixing it's shortcomings.

It's an AmScope stereo microscope that will for the most part, replace my headband magnifier and $15 plastic USB "microscope".

![[Image: 41yMfdtRGtL._SX522_.jpg]](https://images-na.ssl-images-amazon.com/images/I/41yMfdtRGtL._SX522_.jpg)

Unfortunately being an import from China it has a lot of the typical problems right out of the box. First and foremost are the two sliding support rods for the adjustable boom stand. The center support houses some 20mm linear ball bearing sleeves for the upper rod to ride on while sliding back and forth which is great compared to plain bushings. However the manufacturer uses undersized soft steel rods which have a thin chrome flashing applied. Being undersized the rods wobble a bit in the bores. Even worse is that after only a few times sliding back and forth through the hard ball bearing sleeves the chrome on the rod start to compress and begin fretting - making crunchy, crunchy noises and dragging. So the two original rods were the first things to go. I turned two new rods from some properly hardened linear shafting which is a full 20mm OD. Butter smooth operation now.

You can make out some of the fretting in the center of the original shaft below.

The other issues are somewhat familiar to a lot of us I'm sure. Chinese hardware and attention to detail. The fasteners are also undersized and flash chromed. The socket head cap screws wobble in their threaded holes and the hex sockets are sloppy and deformed. I've replaced them with quality stainless steel fasteners. Same for thumb screws.

The focus rack that holds the microscope head to the boom stand rotates on the upper shaft of the boom stand to allow adjustment of the head in that axis. It is locked in position by tightening a lever much like the quill lock on a vertical mill. Two tapered cotters are squeezed together against the shaft to hold it in place. Mine would not even tighten up much less lock in place. I found the cotters were twisted in the bore and only a knife edge of the tapers were contacting the shaft. The shoulder bolt that runs through the cotters was hitting the screws that guide them in the bore. This prevented the cotters from getting pushed far enough into the bore to contact the shaft fully.

I had to re-drill and tap two new holes in the bottom of the focus rack on the center line of the bore for the guide screws and move them in more to allow the shoulder bolt to fully tighten on them.

I also had to re-drill (straight and perpendicular to the shaft center) and install a Helicoil insert for the SHCS that secures the focus rack to the shaft to keep it from pulling off when the lock lever is loosened. The original hole was sloppily drilled and threaded at a 10-15° downward angle, leaving such a loose thread fit that I could almost pull the screw straight out without turning it.

I still need to make an adapter to better secure the camera to the trinocular port. The camera lens just slides down into the port and sits there. The slightest movement of the scope head or USB cable will spin the camera (and your view on a monitor). Ain't nobody got time for that. Hopefully soon I'll be able to begin using it instead of fixing it's shortcomings.

Willie

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)