06-19-2017, 11:33 PM

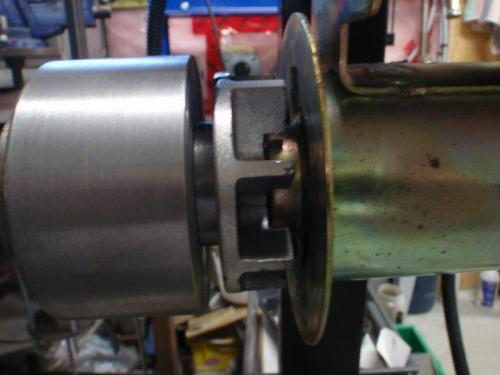

I've been plugging away at building a belt grinder for some time. I've finally reached the point at which it is worth posting. It is powered by a 2 HP DC motor from a treadmill, with a 4" diameter drive pulley. It was necessary to cast an aluminum fan by the lost-foam method, seen here between the pulley and the motor.

The idler pulley has a slightly crowned surface with a tilting yoke to aid in aligning the belt.

The control panel was cut down from the treadmill panel and a box built to house the control board. The markings beside the slider equate to 894 RPM (959 sfpm), 2285 RPM (2452 sfpm), 3506 RPM (3762 sfpm) and 5020 RPM (5400 sfpm).

The platen was made from a piece of 2" x 3/8" steel that turned out to be stainless. A work rest was added. The mounting bracket allows the working portion of the tool to be tilted backward to access the area of the drive pulley for hollow grinding, or forward to use the unsupported portion of belt at the back if desired.

The idler pulley has a slightly crowned surface with a tilting yoke to aid in aligning the belt.

The control panel was cut down from the treadmill panel and a box built to house the control board. The markings beside the slider equate to 894 RPM (959 sfpm), 2285 RPM (2452 sfpm), 3506 RPM (3762 sfpm) and 5020 RPM (5400 sfpm).

The platen was made from a piece of 2" x 3/8" steel that turned out to be stainless. A work rest was added. The mounting bracket allows the working portion of the tool to be tilted backward to access the area of the drive pulley for hollow grinding, or forward to use the unsupported portion of belt at the back if desired.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.