Posts: 642

Threads: 14

Joined: Oct 2013

Location: East Sussex, UK

I'd imagine it's been heat treated. Probably too late now but would it be possible to anneal it in a bonfire then try again, but you may not have enough material left to clean up after any warping.

Andrew Mawson, proud to be a member of MetalworkingFun Forum since Oct 2013.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

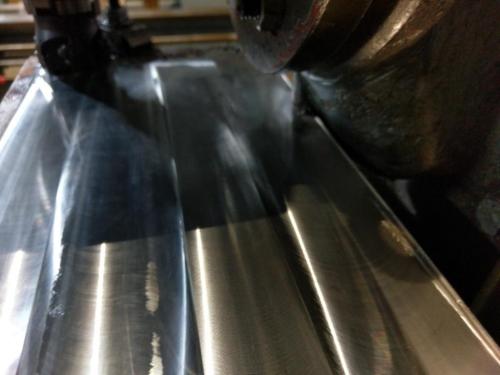

Not a bad thought, I have a big bonfire pile to burn soonish, might be worth chucking this piece and the remainder of the plate on top and see if it's useable afterwards. The piece I was using here is a bit less than half of the chunk I acquired. Would be good if it was at least useful for something.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

Might help, I've run into wear plate, don't think annealing helps as it work hardens. If you can get the hole drilled the sides are hardened in the process and then can't be tapped.

Free advice is worth exactly what you payed for it.

Greg

Posts: 691

Threads: 14

Joined: Feb 2015

Location: Oakland, California

The following 1 user Likes Roadracer_Al's post:

f350ca (04-28-2017)

I know the feeling. I bought some bar stock like that. Even carbide wouldn't touch it.

Regarding what to do with it, find your local blacksmith and sell/give it to them. They are always on the lookout for such materials for making tools & dies. Might even make a hell of a knife.

a

Posts: 2,328

Threads: 271

Joined: Jun 2014

Location: La Libertad, Philippines

04-30-2017, 07:31 PM

(This post was last modified: 04-30-2017, 07:34 PM by Dr Stan.)

(04-28-2017, 08:38 AM)Pete O Wrote: Not a bad thought, I have a big bonfire pile to burn soonish, might be worth chucking this piece and the remainder of the plate on top and see if it's useable afterwards. The piece I was using here is a bit less than half of the chunk I acquired. Would be good if it was at least useful for something.

Get a nice big pile of coals and bury it as close to the middle as possible then let it cool down on its own.

Since you're already going to have the bonfire might as well try it. Nothing ventured, nothing gained.

Cut a test piece after the annealing to see if its machinable. If so find someone with a big tub (Blanchard) grinder to finish the top & bottom at a reasonable price.. A reasonable price should be much less than buying a new piece of material.

Posts: 205

Threads: 3

Joined: Jul 2014

Location: Vermont

That actually worked on a piece of chilled cast iron I had a few years ago. I was a little surprised at the time, since I wasn't sure cast would respond to it, but naturally glad that treatment worked so well.

Whatever that mystery metal is, if it is treatable that way, the main thing is to let it cool slowly -- I buried mine in a bucket of woodstove ashes after it was red hot.