Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

Good enough for a home shop for sure.

I've got 3 different sets of gauge

pins, but not a single gauge

block.

Willie

Posts: 3,799

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

The following 1 user Likes TomG's post:

EdK (11-19-2015)

Definitely good enough for shop use, but I would do a sanity check on them just the same. After all, they were made in China. Clean them and check them with a good, well calibrated tenth reading micrometer. You should make sure they all measure up to what they say they are before trusting them.

Tom

Posts: 340

Threads: 24

Joined: Aug 2014

Location: Seattle, WA

(11-19-2015, 02:03 PM)CNCAZ Wrote: I used to have two sets. The 36 piece and a much larger set, don't recall how many.

I always found myself using the small set as it was more convenient. Finally sold the large set and never missed it.

I bet you get along just fine with the set you have.

I use round space blocks as much as the jo blocks.

I've got a set of the round ones, too. They seem fine for my use.

Mike

SB 10K (1976) Rockwell vertical mill (1967) Rockwell 17" drill press (1946) Me (1949)

Posts: 240

Threads: 30

Joined: Mar 2014

Location: Planeta Rica, Colombia

(11-19-2015, 07:03 PM)TomG Wrote: Definitely good enough for shop use, but I would do a sanity check on them just the same. After all, they were made in China. Clean them and check them with a good, well calibrated tenth reading micrometer. You should make sure they all measure up to what they say they are before trusting them.

Tom

Tom,

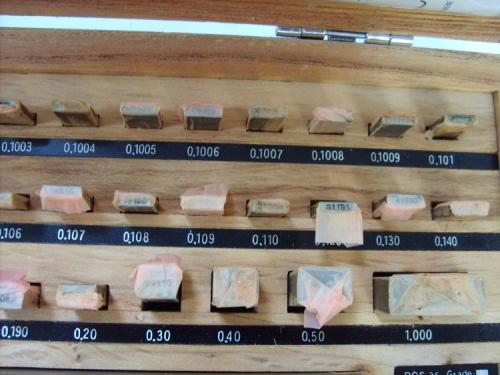

Really good advice. They came with an inspection certificate so in theory somebody checked them to ±0.000050". The certificate shows them to be in spec.

I have a nice, low mileage Starrett 0-1 tenth mike and I'll be able to check everything up to 1". I'll just have to trust the 2" and 4" blocks but they probably won't get much excercise anyway.

JScott

JScott, proud to be a member of MetalworkingFun Forum since Mar 2014.

Posts: 1,520

Threads: 157

Joined: Feb 2012

Location: uk

brill

krv3000, proud to be a member of MetalworkingFun Forum since Feb 2012.

Posts: 1

Threads: 0

Joined: Mar 2016

Location: Ohio

The following 2 users Like Jurskas's post:

EdK (04-05-2016), arvidj (04-05-2016)

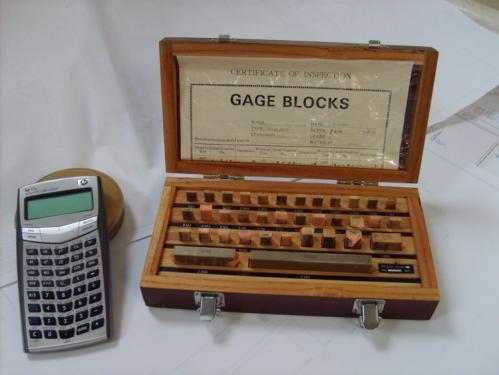

(11-19-2015, 09:49 AM)JScott Wrote: I found a good buy on some new, old stock gage blocks on eBay last week. Made an offer and got this little 36 piece set for a nice price. They are Chinese made, Grade B but they are still in the original preservative wrappings. It takes a block or two more to build a stack but this will be a nice little set for my home shop.

This set has a series of blocks that go from 0.1001" to 0.1009" just in case I need to do some aerospace work!

At present I have a 12x18x3 inch thick granite surface plate, a 36 piece set of spacer blocks, these new gage blocks and a surface gage. Next up is a dial height gauge.

Thanks for looking, JScott.

After checking the blocks up to 1" you can wring them and check the larger blocks with a indicator and surface gage on your plate. Its not the most accurate way but will suffice for any hobby home work.

Eric

Posts: 240

Threads: 30

Joined: Mar 2014

Location: Planeta Rica, Colombia

Jurskas, Thanks for the tip. It will help me finish the last check on the blocks. I haven't started yet due to other projects but I will get to it.

JScott, proud to be a member of MetalworkingFun Forum since Mar 2014.

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)