Posts: 535

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

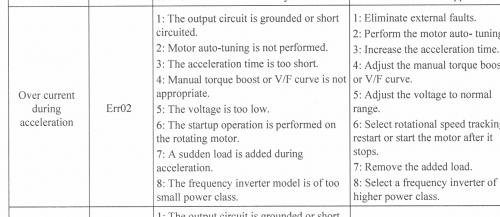

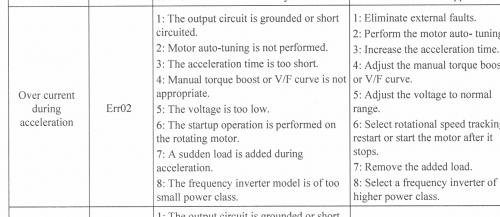

Does anyone here have any experience setting up a KOC100 VFD? I've got everything wired up, including a remote panel (not activated yet). Part of the process involves performing an auto-tuning of the motor. I follow the procedure, set b0-30 to 2, then press 'Run' as directed. It starts the auto-tune, then always ends in an 'Err.02' message.

I've checked for shorts. The only one that seems likely is that the auto-tuning didn't complete. Any ideas?

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Hi Mike

I am no VFD expert ,especially when I dont have the manual lol

#1 OK you have checked for shorts , what with ? is this a new electric motor ?

#2 Forget as this is what you are trying to achieve ,

#3 , have you reduced the acceleration time , if set high this will cause a high inrush current .

#4 ? ref manual

#5 is your mains voltage ok , if low this will cause high current .

#6 ? ref manual ,,,,,,,,,,,,,,,,,, mmmmmmmmmm just a thought , remove remote panel and re run test .

#7 ? doubt it will this

#8 incorrect inverter for the motor , is the inverter rated to the Hp/Kw of your motor

is the motor set to the correct voltage to match the inverter output 110/240 v

Cheers Rob

Posts: 4,463

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

(12-28-2015, 11:16 PM)Hawkeye Wrote: ...... I follow the procedure, set b0-30 to 2, then press 'Run' as directed. It starts the auto-tune, then always ends in an 'Err.02' message.

Mike,

I'm no VFD expert either but odds are, one or more of your parameters is set incorrectly.

Motor type, acceleration rate, SOMETHING.

For starters, the manual I'm looking at only goes up to b0-26.

Willie

Posts: 8,863

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

What's the model number of the VFD? KOC100 is the series.

Ed

Posts: 535

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

The VFD is a KOC100-1R5S2 - rated at 1.5KW, single-phase, 220 Volt input, 7.0 amp output tracking input voltage.

Willie, read page 36. b0-30 is a test setting, not a parameter. The table only goes to -26.

Rob, for reference, I'm a journeyman electrician and an Electronics Engineering Technologist. I used one of my DMMs, set to ohms. All three legs, including cable, are less than 1 ohm different, with no leakage at all to ground.

The motor is unused. All knockouts in the JB are still intact. Mains here are 120/240 VAC, 60Hz. No-load voltage shows 243, which it holds when running my 2 HP table saw.

Default accel time is 10 seconds, which I reduced to 4. Conversely, the trouble table says the opposite - "acceleration time is too short". I'd hate to think it will only run if it is set for 15 or 20 seconds to get up to speed.

The remote panel, as I mentioned, is not yet activated. The VFD is still getting its instructions from its own front panel.

I'm going to try a 1 1/2 HP motor to see if the unit is just not capable of meeting its expectations.

Thanks for the suggestions, guys.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Wow Mike with those qualifications it should be a breeze for you to fault find a VFD ! and it surprises me that one with such qualifications would ask for help with an electrical problem .

Oh well noted for future reference .

I was just doing my best with the limited information in your first post .

My bad I should have wrote low

Quote:#3 , have you reduced the acceleration time , if set high low this will cause a high inrush current .

Reducing the accel time to 4s will increase current draw .

I would have used a Megger and do to test for electric motor insulation faults . DMM,s can lie as using the DMMs 9v internal battery is not a real test of a motor's insulation , but hey what do I know you're the expert

Rob

Posts: 4,463

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

(12-29-2015, 12:09 PM)Hawkeye Wrote: The VFD is a KOC100-1R5S2 - rated at 1.5KW, single-phase, 220 Volt input, 7.0 amp output tracking input voltage.

Willie, read page 36. b0-30 is a test setting, not a parameter. The table only goes to -26.

OK, I have to be looking at the wrong manual then. I searched the whole .pdf and couldn't find "b0-30" on page 36 or anywhere in the entire manual for that matter.

Stupid question..... are you bench testing this motor (no load), or is it connected to a machine? And are you getting a trip indicator along with your err code?

I had the opposite problem with my Hitachi when I was setting it up on my lathe. Mine kept tripping on deceleration due to a buss over-voltage. I had the decel time set too short.

Willie

Posts: 340

Threads: 24

Joined: Aug 2014

Location: Seattle, WA

I had the same problem with the VFD on my mill. I had ramp up and ramp down set to very short times, and it kept dropping out. Extending the times back to the defaults (10 secs., IIRC) fixed it.

Mike

SB 10K (1976) Rockwell vertical mill (1967) Rockwell 17" drill press (1946) Me (1949)

Posts: 535

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

The only reason I changed the ramp times was that the thing wasn't working. I've tried 4, 10 (default) and 15 seconds with no change. Trying the 1 1/2 HP motor only changed the error code from 2 to 4. Almost the same list.

When I changed back to the 2 HP, it actually ran the motor - then gave the Err.02 code again. Then every try was like the first.

So, am I correct in concluding that no one here has used one of these VFDs? I was hoping that someone had done it and knew some trick that the manual didn't explain very clearly. Actually, the manual that came with the unit was Chinese only. Fortunately, when I ordered the VFD, they sent a pdf English version by email.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 8,863

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

Could you post the PDF manual so we can take a look at it?

Ed

|