I'm making a (sort-of) copy of the SB Lathe Tool Grinding Block. The original had a square, broached hole for each size of toolbit. I can't go there, not at $100 for one square broach!

So, I turned down a cylinder, with a larger end. The less said about the quality of the turning, the better. I did this a while back, when I knew even less than I do, now. I'll mill a slot for the toolbit.

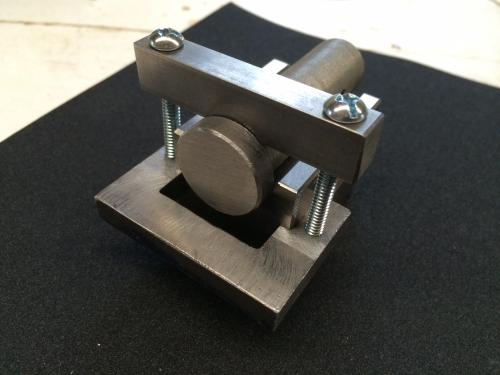

Now I'm faced with the problem of how to secure it, while I mill the channel. The "over-the-top" clamp that came with the v-blocks would get in the way of the spindle. I saw a picture where someone had machined a "C' block to go in the slots in the side of the block, and tapped it for hold down bolts.

Worked great! Now I can clamp it in the vise, indicate it properly, and mill my channel.

So, I turned down a cylinder, with a larger end. The less said about the quality of the turning, the better. I did this a while back, when I knew even less than I do, now. I'll mill a slot for the toolbit.

Now I'm faced with the problem of how to secure it, while I mill the channel. The "over-the-top" clamp that came with the v-blocks would get in the way of the spindle. I saw a picture where someone had machined a "C' block to go in the slots in the side of the block, and tapped it for hold down bolts.

Worked great! Now I can clamp it in the vise, indicate it properly, and mill my channel.

Mike

SB 10K (1976) Rockwell vertical mill (1967) Rockwell 17" drill press (1946) Me (1949)

SB 10K (1976) Rockwell vertical mill (1967) Rockwell 17" drill press (1946) Me (1949)