Posts: 1,520

Threads: 157

Joined: Feb 2012

Location: uk

hi just a tip if you is wonting to weld a crack in a peace that has a hole in it or a bit that's missing make a copper plug to fill the void as the welld will not stick to the copper

krv3000, proud to be a member of MetalworkingFun Forum since Feb 2012.

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

Mark, I have done as krv3000 (Bob) has suggested. It was an aluminum casting that had a cracked off part of a threaded mounting ear.

I threaded a piece of copper to match the half threaded hole and took it to my aluminum welding wizard. He built up the rest of the "ear/tab" and when done and cooled down I unscrewed the copper piece and cleaned up the welding and the part was new again.

Just make sure the copper is smooth and not tapered to aid removal .

P.S. please add London Ont. to your profile so old geezers like me won't wonder where the hell you are in this tiny country of Canada you are.

Steve

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 8,863

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

(07-17-2015, 05:15 PM)turbo711 Wrote: Thanks Dallen and Edk. I am not familiar with this industrial wiring stuff. How do you guys know that they are the right ones? What is the difference between a CN or a CU prefix. I get the NO or NC aux relay thing, and the coil voltage, but what about the main contact arrangement? Can they be normally open or closed? If I get the exact replacement, then I can just wire it in, but if it is different, then I will have to figure out the complete circuit, and that would be a big pain.

Mark

Mark,

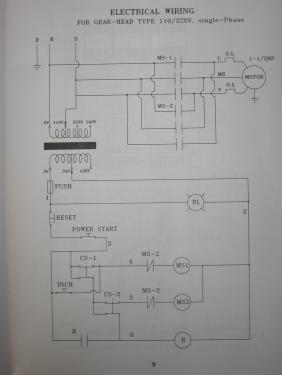

I looked at the datasheets for both the CN and CU versions and I couldn't see any difference. They are both 24VAC coils and 25A normally open contacts so there's no reason either one wouldn't work. The main contacts need to be normally open since the two contactors on the left are what switches the motor direction. If they were normally closed they would short out. See the attached wiring schematic from the manual for my lathe. That might help show the need for normally open contacts.

Ed

Posts: 44

Threads: 3

Joined: Nov 2013

Location: Edmonton, Canada

(07-17-2015, 05:29 PM)turbo711 Wrote: Hello Johnnyc14. I live in London Ontario. I appreciate the milling offer. The slot just has to be milled to make it straight again. No particular dimension. Then I can just make a wider pin to fit. Not sure if the shipping both ways would be more than it's worth... What do you think?

Mark

Mark, if you can figure out what size package it will fit into and weigh it, you can go to the Canada Post website and determine the cost to ship it. My postal code is T8N4H6.

johnncyc14, proud to be a member of MetalworkingFun Forum since Nov 2013.

Posts: 58

Threads: 5

Joined: Jul 2015

Location: London Ontario Canada

Hello guys. The EZ weld tig wire is for welding copper as well. I think the only way to truly weld cast iron is with high nickel rod and preheat the part to over 500 degrees. The part is then welded and allowed to cool very slowly in sand or oven. Probably a preheat over 500 is even better. I am not prepared to attempt it for the crack that is there. I'll just end up making it worse. I can feel it....

I like the FactoryMation link as the contactors are cheap and look similar. I'm going to do some more research before I buy, to make myself feel good about it.

Hello John. I'll look into the package thing on Monday. I got a weekend of 12 hour nights to deal with. Thanks for the tip.

so long for now,

Mark

Posts: 8,863

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

(07-18-2015, 07:26 AM)turbo711 Wrote: I like the FactoryMation link as the contactors are cheap and look similar. I'm going to do some more research before I buy, to make myself feel good about it.

Mark,

Just remember you need two types of contactors. One with a normally open auxiliary contact and two with normally closed auxiliary contacts.

Ed