Had an indifferent day today. In removing the rear cover (again) I noticed that either I stuffed up in recalling where the two short M8 SHCS went (the other four are longer). I could have sworn that they were in the centre holes. Turns out they should have been bottom left and bottom right. As a result, ones has popped through the casting and now lets the reservoir of oil leak out. I am going to fix it but didn't have a M8x1.25 grub screw to (wrap with PTFE tape and) plug the hole. I also need to investigate why there is a reservoir, as the book suggests that the headstock is (effectively) dry.

After adjusting the clutches again, I have now lost the positive hold on reverse and the brake is just as aggressive

I did notice that one of the brass shoes on the fwd/rev selector is missing, which could be the cause.

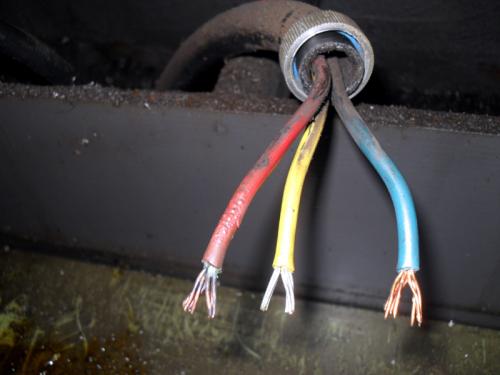

I then set about cleaning up the oil, which gravity takes on a meandering path through the electronics enclosure and the motor bay. In cleaning up I noticed that phase 1 on the motor feed looked worse for wear. It has gotten hot and cooked the wire and insulation. I will have to replace. Most likely cause is a loose connection. You can see it clearly here (red wire):

I decided to remove the actual mounting board and see if the bolts that hold the feed box on were indeed hiding behind here (I read a post on PM that suggested so but there had been some skepticism). I can see four lurking in there. I will need to access these if I need to remove the feedbox

Whilst the paper was soaking up the oil, I decided to remove the jaws on the 3-jaw chuck, as I had been bugging me that someone had put them in out of sequence. I pulled them out and looked at the numbers stamped onto them. I had one "6" and two "7"

A few different combinations later and I found which was which. I then proceeded to stamp them accordingly.

I found the manufacturer's badge hiding behind a layer of crap and to me it appears to be the Bison logo. Although, it doesn't actually say Bison. I punched "PUTm chuck Poland" into Google and din't get anything of use back. I wonder if this is early Bison?

![[Image: BISON-FullColor.jpg]](http://lathe.com/toolmex/BISON-FullColor.jpg)

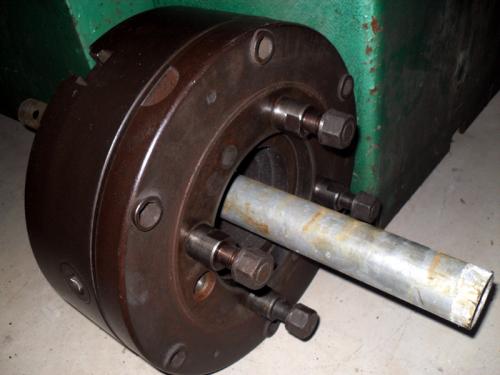

I decided to remove the chuck to check out the DIN55022 mount. It is pretty straight forward and uses a locking ring that rotates to capture the four studs that extend from the rear of the chuck adapter. There is a single locating pin and once in place, the four nuts are tightened. The last pic isn't all that good but it does show the locking ring.

For reference, those are 24mm nuts!

I'll have to keep trying until I get it right!

I'll have to keep trying until I get it right! A few different combinations later and I found which was which. I then proceeded to stamp them accordingly.

A few different combinations later and I found which was which. I then proceeded to stamp them accordingly.![[Image: BISON-FullColor.jpg]](http://lathe.com/toolmex/BISON-FullColor.jpg)

and it looks like there is grease inside the apron as well. I think I am going to have to remove the apron. I'm going to remove the drain plug and see if any oil comes out. If not, I think I'll fill the apron with kerosene to (hopefully) dissolve the grease.

and it looks like there is grease inside the apron as well. I think I am going to have to remove the apron. I'm going to remove the drain plug and see if any oil comes out. If not, I think I'll fill the apron with kerosene to (hopefully) dissolve the grease.