Posts: 8,889

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

My next project is to make Tom's clamp knurling tool. I've needed a knurling tool for a long time now so when I saw Tom's thread on his knurling tool, that project jumped to the top of the list.

I've had a new Kurt D675 vise for awhile now and was saving it for when I got a bigger mill. I didn't think it would fit well on my bench-top mill but since getting a bigger mill is still a ways off, I decided that this project would be its maiden voyage. I had to build a lifting aid so I could get it up onto the mill table. My old fart back can't handle the lifting like it use to and I don't want to risk injury so I built the lifting aid that bolts to the vise. I used my cherry picker to lift it up onto the table. Overkill? Hell yes but my back thanks me.

Ed

Here are a couple of pictures of the vise on the mill.

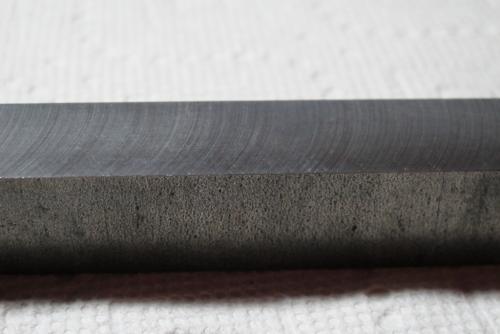

And just so this post is actually related to the project, here's the blank I cut out from some 3/4" plate for the knurl holders.

Posts: 8,889

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

I started machining the knurl holders today following Tom's video as much as I can. He used a fly cutter to machine the holders so I decided to do the same, even though I've never used a fly cutter before despite having one for years. So I ground the cutter and gave it a try. I'm not sure if the finish I got is typical for fly cutters so I thought I'd post some pictures to get opinions from those that have used fly cutters before. There are ridges in the finish that I can feel with my fingers. I don't have power feed on the mill table so that might be the reason but I fed the table as slow and smooth as I could. I know it won't matter to the functioning of the tool but I'd like to know whether I'm doing something wrong with the fly cutter.

Ed

Posts: 3,799

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

Hey Ed,

It looks like you need a slightly larger radius on your tool bit and the head on your mill is out of tram. You should see a nice cross hatch pattern.

Tom

Posts: 8,889

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Tom,

Thanks for the advise. I'm pretty sure the mill head is trammed because I got a cross-hatch pattern using an end mill while making the spin indexer tail stock. But, I'll check it to be sure. I'll increase the radius on the tool bit after checking the tram and try another pass with it tomorrow.

Ed

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

I cheated and used brazed on carbide lathe bits to make my holders out of

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

The following 3 users Like PixMan's post:

EdK (01-01-2015), Mayhem (01-01-2015), wrustle (01-03-2015)

That would have been a great application for your Walter F4041 cutter, Ed.

As for the flycutter, I use brazed carbide tools on the rare occasion that I use mine, and one their cutting edge I grind a large radius. That gives a superior finish at nearly any feed rate.

When the day comes that you can upgrade to a larger, more robust milling machine, you're going to LOVE that vise and the cutter!

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Hi Ed,

Fly cutting on the mill can be considered analogous to cutting on a lathe - single point tool bit except the tool bit moves and the work piece is stationary plus it is an interrupted cut.

I agree with Tom the tool tip bit needs a radius. Also keep the "over hang" as short as possible (that's the over hang of everything). Every thing needs to be rigid.

Also I have found fly cutting aluminium and cast iron is a lot easier than plain steel. Maybe there is less "bounce" with aluminium and cast iron?

The initial angle at which the tool hits the work piece can also make a difference a shallower angle can sometimes help.

I would not have used a fly cutter I would have used a small face cutter (I'm sure you have one) - this is not being defeatist - it is using what I think is the best tool for me.

Using a fly cutter with hand feed is also more difficult to get a nice finish but a radius on the tool tip will help.

DaveH

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

(12-31-2014, 09:20 PM)EdK Wrote: Tom,

Thanks for the advise. I'm pretty sure the mill head is trammed because I got a cross-hatch pattern using an end mill while making the spin indexer tail stock. But, I'll check it to be sure. I'll increase the radius on the tool bit after checking the tram and try another pass with it tomorrow.

Ed

Ed a smaller diameter endmill compared to a fly cutter is much more likely to produce a "cross hatch" pattern.

The radius of the flycutter tool tip is much greater and so will show the "out of tram" condition much clearer.

Steve

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 8,889

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

OK, I checked the radius of the cutting tool tip and as near as I can measure using number drills, it's about .020-.025". So it's already larger than the radius recommended on Tom's chart for fly cutters.

Next I went to check the tram and decided to sweep the parallel first to see how it looked and it was within .0003-.0004 so I'm not real inclined to take the Kurt mill off of the table to sweep it for tram. Any thoughts?

Thanks,

Ed

Posts: 3,799

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

Does it make that pattern feeding in both directions? If so, it's possible that there isn't enough relief on the cutter and it's dragging behind the cutting edge. Also, what alloy is the steel? If it's 1018, that might be a pretty good finish.

Tom

|

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)