I have a kinetic plastic hammer style bullet puller for "erasing" loading mistakes but it almost always mashes the tip of the spitzer bullets I favor. I wanted a type of puller that grasped the bullet without marring or damage.

This style of puller is available but along with the collet pullers it is very expensive (I'm cheap!).

Picture1.jpg (Size: 7.76 KB / Downloads: 109)

Picture1.jpg (Size: 7.76 KB / Downloads: 109)

I used an idea from a magazine article of using a side cutting pair of pliers to hold the bullet and pull it from the case using a reloading press in reverse. That sounded like it would work but I didn't want the little grooves cut into the bullet jacket.

To make my prototype I started with these pliers from Harbor Freight for $2.99.

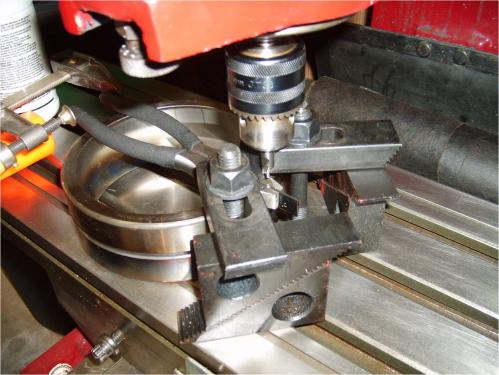

Next I clamped it to the mill table using a bearing race as a setup block. I put two shims of steel banding tape between the tips of the jaws to leave some final clearance and then center drilled the jaws. The shims measured right at 0.045 inches.

After the center drill, I used a size L drill bit (0.290 inch diameter) so that I could pull 0.277 and .0284 inch diameter bullets. I used a Harbor Freight drill bit on the Harbor Freight pliers in a head to head battle using some dark cutting oil.

Here is the finished prototype puller after drilling and chamfering. It turned out pretty good. The drill bit won but it complained a little bit because of the interrupted cut. The dark cutting oil helped I think.

And here is the puller holding a 0.277 inch diameter bullet. The fit is very good and it almost looks professional.

I tried pulling a bullet with it and it did not have enough gripping force to pull the bullet. I cheated by using my kinetic puller to get the bullet started out of the case and then used the plier to finish pulling the bullet. It worked perfectly without marring or damaging the bullet. I am going to stamp this one 27-28 and make some others in .224, .243, .257 and .308 flavors.

This style of puller is available but along with the collet pullers it is very expensive (I'm cheap!).

Picture1.jpg (Size: 7.76 KB / Downloads: 109)

Picture1.jpg (Size: 7.76 KB / Downloads: 109)

I used an idea from a magazine article of using a side cutting pair of pliers to hold the bullet and pull it from the case using a reloading press in reverse. That sounded like it would work but I didn't want the little grooves cut into the bullet jacket.

To make my prototype I started with these pliers from Harbor Freight for $2.99.

Next I clamped it to the mill table using a bearing race as a setup block. I put two shims of steel banding tape between the tips of the jaws to leave some final clearance and then center drilled the jaws. The shims measured right at 0.045 inches.

After the center drill, I used a size L drill bit (0.290 inch diameter) so that I could pull 0.277 and .0284 inch diameter bullets. I used a Harbor Freight drill bit on the Harbor Freight pliers in a head to head battle using some dark cutting oil.

Here is the finished prototype puller after drilling and chamfering. It turned out pretty good. The drill bit won but it complained a little bit because of the interrupted cut. The dark cutting oil helped I think.

And here is the puller holding a 0.277 inch diameter bullet. The fit is very good and it almost looks professional.

I tried pulling a bullet with it and it did not have enough gripping force to pull the bullet. I cheated by using my kinetic puller to get the bullet started out of the case and then used the plier to finish pulling the bullet. It worked perfectly without marring or damaging the bullet. I am going to stamp this one 27-28 and make some others in .224, .243, .257 and .308 flavors.

JScott, proud to be a member of MetalworkingFun Forum since Mar 2014.