Posts: 537

Threads: 15

Joined: Jun 2012

Location: Cambridge, England

06-13-2012, 10:24 AM

(This post was last modified: 06-13-2012, 01:09 PM by EdK.)

Quote:Hi Rick,

I did ask, and I was referring to the drawing that Ed posted in post #36 the left hand drawing. There is always that "big gap"......... so I aim for the radius part and go from there.

Thanks Rick

DaveH

Hello Dave

A good rule of thumb is to point the wire at whichever side of the weld has more mass/density, in this case it's the radiused corner as effectively there is twice as much metal there with two faces joining at the radius, the same is true when butt welding dissimilar thickness plates, point at the heavy plate.

Sorry Ed,

It makes more sense now though, but as you now know there is no weld prep required on that particular style of joint, the edge radius sort of provides the ideal weld prep, just as long as you aim toward the heavy side.

The radius is designed specifically with welding in mind, it is a sort of "happy compromise" between the radius required to form a good rectangle, that can also be formed in a tube bender and a weld prep shape, as 90% of stuff made from rectangular tube has that exact welded joint and probably the same percentage of under 1" square tube products uses the radius formed corner bends.

Anyway, it seems my post was helpful so mission accomplished.

Best regards

Rick

Whatever it is, do it today, Tomorrow may not be an option and regret outlasts fatigue.

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Rick,

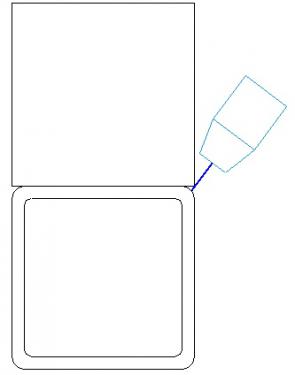

Is this what you mean by angling the wire towards the fillet? See sketch below.

Thanks,

Ed

Posts: 537

Threads: 15

Joined: Jun 2012

Location: Cambridge, England

The following 1 user Likes Rickabilly's post:

DaveH (07-07-2015)

Yeah, pretty much,

But I'd lay the joint flat on the bench, it's easier to let gravity drop the weld metal where you want it, rather than trying to keep it up on the side like that, so rotate your image 90 degrees anti clockwise and then lift your torch up to about 60degrees above horizontal and off you go.

Best Regards

Rick

Whatever it is, do it today, Tomorrow may not be an option and regret outlasts fatigue.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Thanks Rick,

It is always good to know the "best" way to do it, even though it very rarely works for me.

DaveH

Posts: 537

Threads: 15

Joined: Jun 2012

Location: Cambridge, England

Don't Worry Dave, We'll make a Welder out of you one day

Whatever it is, do it today, Tomorrow may not be an option and regret outlasts fatigue.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(06-14-2012, 09:16 AM)Rickabilly Wrote: Don't Worry Dave, We'll make a Welder out of you one day

Rick,

I live in hope as well

DaveH

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Resurrecting this old thread. I plan on finally getting around to practicing some welding this weekend. I'll post pictures for critique despite my embarrassment.

Ed

Posts: 537

Threads: 15

Joined: Jun 2012

Location: Cambridge, England

No embarrassment required,  if you try that is.

To all those others too scared to give it ago,  Shame,  Shame,  Shame,

But seriously, give it a go, post the results, and I'm sure we can give some feed back, It wouldn't hurt to note down the welding settings used on each run and the specs for the machine and consumables as well.

Regards

Rick

Whatever it is, do it today, Tomorrow may not be an option and regret outlasts fatigue.

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Will do Rick. I'm going to pick up some 1/8" steel today to practice on. The roll of wire I have on the welder now has been on there for almost a year now out in the garage with extremes of temperature and humidity so I may have to put a new roll on.

Ed

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

09-15-2012, 09:20 AM

(This post was last modified: 09-15-2012, 09:21 AM by dallen.)

Ed any wire that you go buy will probably of been stored under the same conditions, unless its rusty there will be nothing wrong with it.

get some scrap and practice setting the machine or as someone said use the autotune (myself I probably wouldn't like what the machine came up with) set your voltage and adjust the wire speed to suit.

remember three things

1. travel speed of the gun

2. speed of the wire

3. voltage setting on the machine.

Most people make welding out to be one of the dark secrets, but its actually just some techniques,

and what works for one person may not work for you.

DA

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

|