Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

My old Lincoln has that ramp up feature on the wire speed. If I remember correctly, the manual says it gives the wire time to heat up and start the puddle before pilling on the filler. I've tried turning it off, I get an ugly cold blob at the beginning of the weld with out it.

Greg

Free advice is worth exactly what you payed for it.

Greg

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

(04-13-2012, 07:19 AM)EdAK Wrote: I've never noticed that and the manual doesn't say anything about that feature. I'll have to watch for it the next time I fire up the welder.

Ed

You might not notice it at all if the wire speed is set at the lower end of the scale. If you crank it up to the upper end, you'll see the difference.

Willie

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Thought I'd post a couple of pics of my old welder.

From Left to Right: The 3 phase on/off switch and wire spool motor on/off switches I installed. (top row) weld time and dwell time, (bottom row) wire speed and voltage.

Hunting American dentists since 2015.

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Mayhem,

That welder looks like a tank. I'll bet it weighs a ton.

Ed

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

It is a two person lift!

Hunting American dentists since 2015.

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

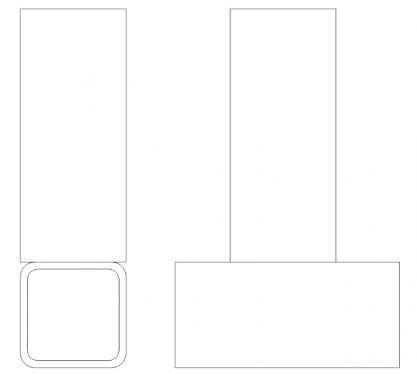

Question. How do I T-weld square tubing? With the radius' on the corners, there is a gap where there is no metal to metal contact so I can see easily blowing through. The only way I can see closing that gap is to form the end of the tubing to match the radius' and that seems like a whole lot of work. This is 1 1/4" 14 gauge (.083") square tubing. See attached sketch.

Ed

Posts: 1,459

Threads: 159

Joined: Feb 2012

Location: Northern England

Hi

Ed

Box section is easy to weld the gap will fill in no problem

What you need is someone to help you set up your welder and give you a few pointers

Once you get set up you will be suprised how easy it is to get good results.

You can tell when a MIG is running well by the sound it makes

It should sound like bacon crackling in a frying pan.

Get some scrap bits of box section start welding them and adjust the power and wire feed rate as you weld

If it spits and tries to push you away you need more power less wire

If it blows holes you need less power more wire

Once you get a feel for it you will be fine

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Thanks John. I guess I just need more "stick time" to get the process down. I think it's finally spring here in Minnesota, lilacs are blooming, so welding weather should be here for a few months now.

Ed

Posts: 1,459

Threads: 159

Joined: Feb 2012

Location: Northern England

Once you get a "feel for what the welder is telling you) it will all fall in to place

John

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

John,

For the 14 gauge tubing, (.083") should I be using the .025" or .030" wire? Or maybe it doesn't matter and is more dependent on the wire feed and power settings.

Ed