Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

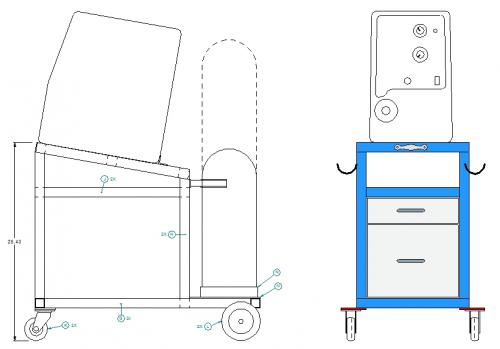

I have drawn up plans for a welding cart for my Millermatic 180 MIG welder some time ago but I suck at welding so I haven't tackled it yet. I have all of the material cut to length. See attached sketch.

I need some help on what to set my welder to for welding the the 1 1/4" square tubing which is 14 gauge, (.083") thick. In the past when I've tried to weld 14 gauge steel I just seem to blow through it too easily and give up in frustration. I'm to the point where I want to, no need to, get past this and learn what I'm doing wrong. I have both flux core and solid MIG wire along with 75/25 gas. I need help.

aametalmaster, you out there?

Ed

Posts: 126

Threads: 23

Joined: Apr 2012

Location: houston pa

04-06-2012, 08:32 PM

(This post was last modified: 04-12-2012, 05:18 AM by DaveH.)

it sounds simple, try the next setting down? if you have fit up thats not the best with gaps it is easier to burn a hole. if you do burn a hole let it cool a bit and you can turn your settings down increase your stickout length or increase your gun angle to put more heat back onto the weld.

even the type of material you have will change how it welds so what might work for this wont for that.

75/25 would be better if your having trouble with holes.

pay close attention to whats happening and what things look like just before making the hole (not always easy) and you might be able to stop before you have the problem.

if worse comes to worse stitch weld it up. shouldnt take long that way at all

make sure polarity is correct before you start.

mikecwik, proud to be a member of MetalworkingFun Forum since Apr 2012.

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

04-06-2012, 11:08 PM

(This post was last modified: 04-06-2012, 11:20 PM by Highpower.)

Ed,

Gun lead connected to Pos, ground lead connected to Neg.

Use solid wire, 75/25 gas, regulator set to 20 cu. ft. / min.

Purge the gas line for 2 - 3 seconds before you start your first bead only. (No wire feed.)

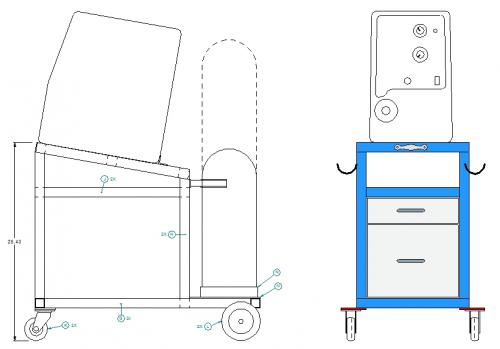

Set your wire speed to .024 (or) .030 to match the wire size you are using. The blue "auto-set" light should be ON.

(Where it is now in the picture if you are using .030 wire.)

Set the voltage to approx 5.2 on the dial. Note the green & blue bands above where it shows "14ga" between two of the hash marks? That is your usable range for the wire size you are using - if you need to go up or down on the power to fine tune your arc. That is the beauty of the "Auto-set" system.

Clean the metal down to bright and shiny where ever you want to run a bead with a flap disk, roloc, grinder, whatever. Just make sure you remove any mill scale. Makes it much easier to weld.

And do your welding in an area that blocks any breezes from getting to your work. Outside in the wind isn't going to work. :smiley-rolleyes004:

That is what flux-core is used for....

Practice on a couple pieces of scrap metal before hand and adjust the voltage (if you need to) until you get a smooth, steady, sizzle sound out of the gun as you are moving along. Just run a bead on top of a flat plate. No need to put pieces together yet. You are just trying to get to that proper sound. No popping or sputtering noises!

See how that works out for you.

Willie

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

04-07-2012, 06:26 AM

(This post was last modified: 04-07-2012, 06:27 AM by Mayhem.)

I've never run a welder with any auto settings but the way I set mine up is as follows:

1. Select a suitable power rating for the material .

2. Take a scrap piece of the material you intend to weld and whilst laying down a bead, adjust the wire feed until you find the sweet spot (listen to the weld as described above). Adjust the wire feed whilst welding. Don't start, stop, adjust, start etc.

The wire feed will affect the penetration of the weld, not just the voltage. Keep the wire stick out short and run the wire at the front of the puddle. Practise, practise, practise!

Hunting American dentists since 2015.

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

(04-07-2012, 06:26 AM)Mayhem Wrote: Adjust the wire feed whilst welding. Don't start, stop, adjust, start etc.

The wire feed will affect the penetration of the weld, not just the voltage. Keep the wire stick out short and run the wire at the front of the puddle. Practise, practise, practise!

Mayhem,

That is all good advice.

But just so we don't confuse Ed at this point, and FYI:

When Ed's machine is in the auto-set "mode" the wire feed is tied electronically to the voltage setting. If you raise the voltage knob, the welder automatically increases the wire feed along with it to match the voltage setting. Miller designed these machines to make it easier for NEW welders to get up and running, by allowing them to only have to adjust one knob instead of two.

If the wire feed knob is not in one of the auto-set positions, then the machine is in the normal mode when you have to set the voltage and amperage individually like any other mig machine.

But for now, it might be best if Ed uses the "one dial" method until he gets the hang of finding the sweet spot.

JMHO. :shy:

Willie

Posts: 410

Threads: 77

Joined: Mar 2012

Location: Salem, Ohio

(04-06-2012, 07:14 PM)EdAK Wrote: aametalmaster, you out there?

Yup but i think my mates sumed it up pretty good. Show us some pics when you get going...Bob

Bob Wright

Metal Master Fab

Salem Ohio

Birthplace of the Silver and Deming drill bit.

5 Lathes, SBL Shaper, Lewis Mill, 7 drill presses, 5 welders...

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

OK guys, I tried all of those suggestions last summer and still got lousy results. That was then, this is now so I'm starting fresh and will try the suggestions and post my results so you can help me diagnose my problems.

Ed

Posts: 410

Threads: 77

Joined: Mar 2012

Location: Salem, Ohio

Use the solid wire and gas starting out. I am not a fan of gasless FC wire at all...Bob

Bob Wright

Metal Master Fab

Salem Ohio

Birthplace of the Silver and Deming drill bit.

5 Lathes, SBL Shaper, Lewis Mill, 7 drill presses, 5 welders...

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(04-07-2012, 06:21 PM)aametalmaster Wrote: Use the solid wire and gas starting out. I am not a fan of gasless FC wire at all...Bob

Bob,

OK, I'll save the fluxcore stuff for outside welding and stick with gas shielded wire.

Thanks,

Ed

Posts: 576

Threads: 18

Joined: Feb 2012

Location: Washington State USA

Bob,

I'm curious, what problems do you find with fluxcore I'm not disagreeing. I too have trouble with flux core but seeing as I have yet to afford a bottle of gas it's ether that or stick.

Jerry.

ETC57, proud to be a member of MetalworkingFun Forum since Feb 2012.

|