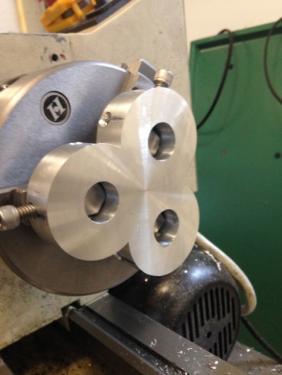

These things work great. Here's the new 3/4" set I made.

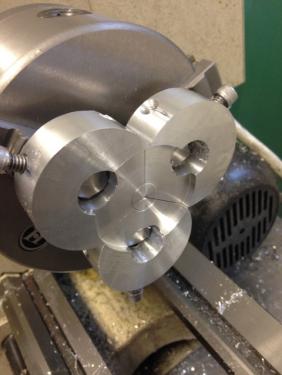

After thinking about it last night I realized that unlike regular soft jaws these can be pre-loaded

against themselves. In other words, instead of tightening them against a ring or a disk you can instead

slip something the same thickness between the flat of the jaws themselves. I took some .002" brass shim

stock and cut three pieces approx. 3/4" X 1" and slipped them between the flats of the jaws then tightened back down.

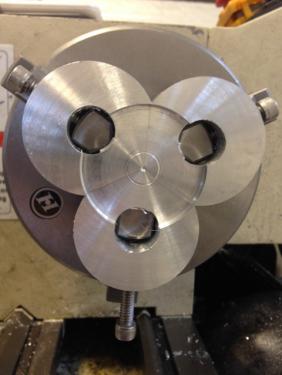

I've got a tiny little boring bar I ground out of HSS that I used after drilling out a hole about 3/16" dia by 3/16" deep.

One of the advantages of these over normal soft jaws is that it's much easier to measure the actual diameter you're boring too.

Another advantage is there's a much larger area that you're gripping onto. I now think of these more as soft collets than soft jaws.

I pulled a piece of 2" dia scrap to test with.

I didn't get pictures of it but I faced off the scrap piece taking fairly heavy cuts. It worked great.

The piece felt very secure. All in all I think these things will be very versatile and make a very

addition to the shop. Also if you don't have a four jaw chuck and need to very accurately re-mount a piece keep these

in mind.

If it's crazy but it works, it's not crazy.