Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Thanks for looking guys

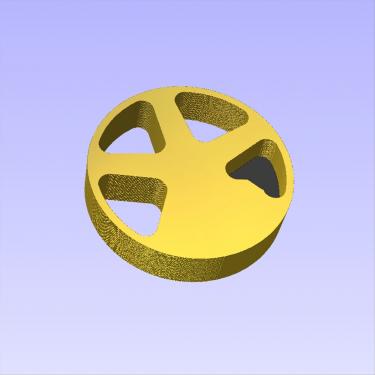

Here are a couple of drawings to show what I was going to make.

I redrew them the originals are terrible

And I was only going to make this on the sherline lathe and mill, so that I would get use to using them and they would get use to me swearing at them

Now the only part I would use the CNC mill is for the flywheel.

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Just to show my "messy" drawings here is one - I have some even worse

DaveH

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(11-11-2013, 06:36 AM)DaveH Wrote: Just to show my "messy" drawings here is one - I have some even worse

DaveH

Dave,

There is nothing wrong with that. I assume those are on the work space. You just need to place them on the paper space to make them look like real CAD drawings with borders and title blocks.

Ed

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(11-11-2013, 07:07 AM)EdK Wrote: Dave,

There is nothing wrong with that. I assume those are on the work space. You just need to place them on the paper space to make them look like real CAD drawings with borders and title blocks.

Ed

They are in paper space (A4)

I just keep altering the scale to fit all the drawing bits in.

I know it is not the correct way to draw in CAD I'm just lazy

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Most of the parts are straight forward turning and milling. The only bit I'm using the CNC mill is to cut out the spokes.

To do this I need to use Cut2D this program will write the Gcode so the the machine will cut out the spokes.

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Load or draw the flywheel (part of) into Cut2D just the part that needs cutting.

Next do the tool path and cutting procedure.

Cut2D shows how the spoke will be cut out. This is animated and was stopped part way through.

Completed, hopefully that is how the machine will cut it.

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

The following 1 user Likes DaveH's post:

Hawkeye (11-12-2013)

11-11-2013, 10:53 AM

(This post was last modified: 11-11-2013, 10:56 AM by DaveH.)

All the CNC mill is going to do is cut out the spokes. The flywheel was made first on the lathe - the centre hole, recesses the boss etc.

Really a finished flywheel except for the spokes.

Couple of pics cutting the spokes.

Finished, still needs to be cleaned up and polished

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

The following 1 user Likes DaveH's post:

stevec (11-11-2013)

11-11-2013, 11:00 AM

(This post was last modified: 11-11-2013, 11:04 AM by DaveH.)

All cleaned up and polished and a sense of the size.

DaveH

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Very nice Dave.

Was that 3D drawing done in TurboCAD?

Ed

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(11-11-2013, 11:01 AM)EdK Wrote: Was that 3D drawing done in TurboCAD?

Ed

Ed,

The 3D drawing was done in Alibre

I tried 3D in TurboCad, I couldn't get to grips with it.

DaveH