Posts: 1,459

Threads: 159

Joined: Feb 2012

Location: Northern England

The only part that can "slip" is the job in the chuck / collet

Check all the key ways ect in the gear train

John

Posts: 375

Threads: 53

Joined: Jun 2013

Location: Jonesborough, TN

Ed, looks to me (a real novice) that there is some backlash or slop somewhere in the gear train driving your leadscrew. Possibly a sheared key? I too, would advise leaving the half nuts engaged and reverse the lathe. I do it for all threading, metric or imperial, and my lathe has a 16 tpi imperial lead screw. Just try it and see if you're results improve.

Chuck

Micromark 7x14 Lathe, X2 Mill , old Green 4x6 bandsaw

The difficult takes me a while, the impossible takes a little longer.

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

You have the correct change gears loaded up for doing imperial threads, yes?

Swapping them to do metric threads and forgetting to put them back will do that to you.

Might want to check that the gear on your threading dial hasn't come loose as well. Been there - done that.

Willie

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Ed,

Just wondering if you set the compound slide over to 29/30 degs to do your screw cutting, or do you go straight in?

DaveH

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

John,

Nothing I can see is slipping, but obviously something has to be and if it is, it's doing it very precisely and consistently. I'll investigate that some more.

Chuck,

All lathes have some backlash but it would be taken up once the tool starts moving towards the headstock.

Willie,

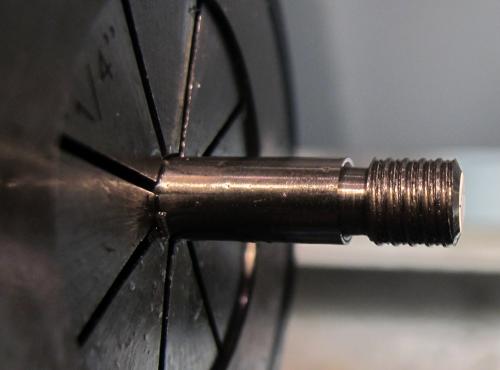

The change gears are correct, otherwise I wouldn't be getting the correct TPI. I did triple check them though. My lathe does not have separate gears for imperial and metric. You swap places of two large gears to change from imperial to metric and I did check those. I also checked the threading dial gear, that's one of the first things I suspected.

I did try cutting the threads with the half nuts engaged at all times and it did cut the thread correctly, but I already knew it would. So I'm still perplexed as to what is going on. I think I'll sleep on it and maybe I'll have an answer come in a dream.

Ed

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

I hate to say this but, If the threading dial sports an "INDICAOR TABLE" any number of other things could be wrong.

Willie's thought about the thread indicator gear having loosened is worth checking out.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(10-22-2013, 04:25 PM)DaveH Wrote: Ed,

Just wondering if you set the compound slide over to 29/30 degs to do your screw cutting, or do you go straight in?

DaveH

Dave,

I have it set at about 29 degrees. Angled or straight in shouldn't cause it to cut two threads though.

Ed