08-19-2013, 04:38 PM

Yesterday I started building the horizontal fence for the Delta sander. Material was procured from the local steel supplier and aluminum remnant supplier. The steel was cheap, the aluminum was pricey. I decided to build two sets of fences, one for myself and another for a good friend. The drawings are done so yesterday was the time to start making chips.

I decided to start on the long fence first. The one I am making is three inches shorter than the one shown in the Delta manual, reason my piece of material came up a little short when it got home. I made changes in the drawings to reflect the shortfall.

Here is a picture of the fence just before I welded the ends on it:

Welding complete:

Welds cleaned up ready for fastners:

The fence will have two arms attached to it that will be secured with bolts to the top of the sander. There will be two positions the fence can be fixed, one when it is used alone and one when it is used in conjunction with the cross fence. This will require two separate attachment points located two inches apart.

The mounting arms are going to be made from aluminum and will be fastened to the fence with 1/4" x 1 x 20 cap screws. the hollow fence will have pieces of 1/2" round stock welded into the fence face and tapped for the 1/4" x 20 cap screws.

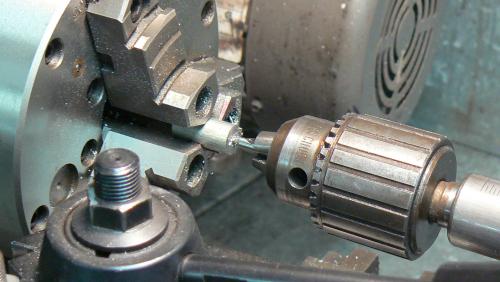

Here is a picture of the fastening points being prepared to be drilled and tapped:

Tapping these fasteners is difficult, I have already broken one tap and have fifteen more to go when I get back out in the shop next week.

I decided to start on the long fence first. The one I am making is three inches shorter than the one shown in the Delta manual, reason my piece of material came up a little short when it got home. I made changes in the drawings to reflect the shortfall.

Here is a picture of the fence just before I welded the ends on it:

Welding complete:

Welds cleaned up ready for fastners:

The fence will have two arms attached to it that will be secured with bolts to the top of the sander. There will be two positions the fence can be fixed, one when it is used alone and one when it is used in conjunction with the cross fence. This will require two separate attachment points located two inches apart.

The mounting arms are going to be made from aluminum and will be fastened to the fence with 1/4" x 1 x 20 cap screws. the hollow fence will have pieces of 1/2" round stock welded into the fence face and tapped for the 1/4" x 20 cap screws.

Here is a picture of the fastening points being prepared to be drilled and tapped:

Tapping these fasteners is difficult, I have already broken one tap and have fifteen more to go when I get back out in the shop next week.

ml_woy, proud to be a member of MetalworkingFun since Jul 2012.

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)