Last week I saw an ad for a Douglas shaper for sale in Albany, some 430km (267mi) South of me. So I did a little reading about them and sent several questions to the seller and decided to drive down and take a look yesterday. Ten hours and fifteen minutes later, I had it back home

I had sat in the corner of this guys shop unused for several years, so there was no plug on it and it was covered in dust. It had been used exclusively for cutting keyways in pulleys. Whilst he had never used the auto feed, he was confident that it worked. Turning the drive pulley cycled the ram and the ratchet clicked forward but didn't seem to disengage and actual pulled the ratchet back - effectively rocking the table.

After getting it home, I unloaded it, put on a plug, oiled the ways and hit the green button. The ram actually travels faster than I expected and really hits hard on the return stroke. The motor is a new one, so it may actually be too fast. Alternatively, I may have screwed something up when I removed the ram to clean the old oil from the ways. What are the possible causes for the ram hammering home?

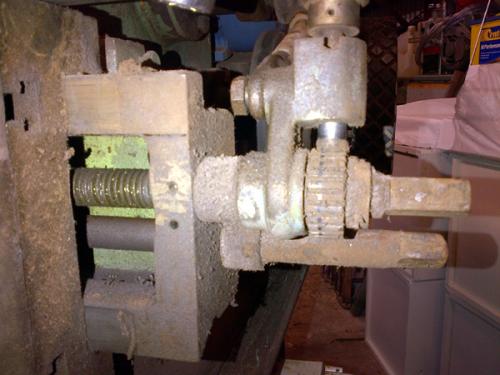

The ratchet mechanism and the gear it drives is covered in years of dust and I will give it a good clean and hopefully see what is happening. In reality, I need to do some reading and looking at youtube to learn how to adjust and use one properly.

OK the pics:

I had to laugh when my GPS told me I had gone off road!

Here is a link to the lathes.co.uk page on these shapers.

I had sat in the corner of this guys shop unused for several years, so there was no plug on it and it was covered in dust. It had been used exclusively for cutting keyways in pulleys. Whilst he had never used the auto feed, he was confident that it worked. Turning the drive pulley cycled the ram and the ratchet clicked forward but didn't seem to disengage and actual pulled the ratchet back - effectively rocking the table.

After getting it home, I unloaded it, put on a plug, oiled the ways and hit the green button. The ram actually travels faster than I expected and really hits hard on the return stroke. The motor is a new one, so it may actually be too fast. Alternatively, I may have screwed something up when I removed the ram to clean the old oil from the ways. What are the possible causes for the ram hammering home?

The ratchet mechanism and the gear it drives is covered in years of dust and I will give it a good clean and hopefully see what is happening. In reality, I need to do some reading and looking at youtube to learn how to adjust and use one properly.

OK the pics:

I had to laugh when my GPS told me I had gone off road!

Here is a link to the lathes.co.uk page on these shapers.

Hunting American dentists since 2015.

or two

or two ![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)