As promised to Ed I have done the mod.

It has only taken me 6 or so years after fitting the DRO to do this, LOL

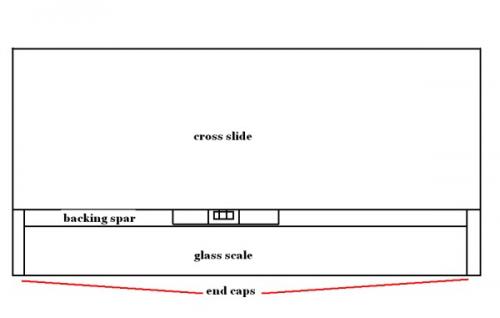

I had a backing spar behind my glass scale on my 12 x 36 lathe and it covered the cross slide lock, so this is the solution I came up with. I don't run coolant as yet so I only had to worry about the chips.

I removed it today, but forgot to take pictures of the main part. It was such a hassle to replace because I left the scale in place and the new bolt was sticking out, so I just drew a picture of the part and took photos of the finished thing (sorry)

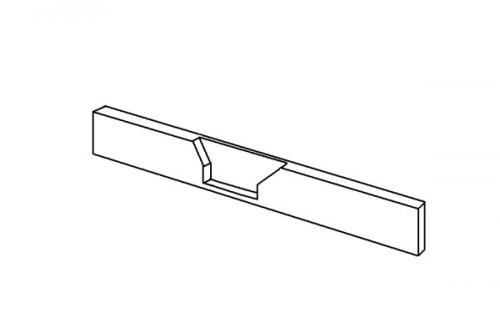

Picture one is what shape I found the spanner fitted best and I just milled it out.

Installed, it was hard to get a good picture with the phone so I posted them all.

I decided to put a cover on it and then found it was hard to get out, so a touch with an end mill gave me a finger nail edge to get it out. My scale sits above the cross slide about 2mm so this was helpful.

Dave

It has only taken me 6 or so years after fitting the DRO to do this, LOL

I had a backing spar behind my glass scale on my 12 x 36 lathe and it covered the cross slide lock, so this is the solution I came up with. I don't run coolant as yet so I only had to worry about the chips.

I removed it today, but forgot to take pictures of the main part. It was such a hassle to replace because I left the scale in place and the new bolt was sticking out, so I just drew a picture of the part and took photos of the finished thing (sorry)

Picture one is what shape I found the spanner fitted best and I just milled it out.

Installed, it was hard to get a good picture with the phone so I posted them all.

I decided to put a cover on it and then found it was hard to get out, so a touch with an end mill gave me a finger nail edge to get it out. My scale sits above the cross slide about 2mm so this was helpful.

Dave