Hi Guys,

I recently had a need for a thin parting tool. So I set to and made this one !

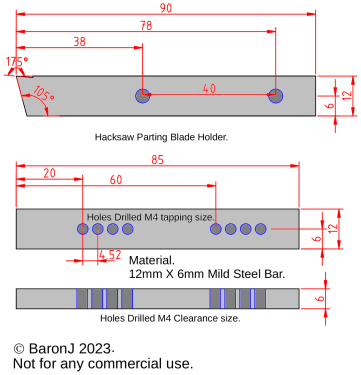

I used a broken hacksaw blade and made a holder for it, the drawing below shows the dimensions that I used.

The holes are there to hold the two pieces together and allow the hacksaw blade to be moved forwards in 5 mm steps. Also the maximum stick out is limited to 20 mm. The whole thing is designed to fit into the front or rear tool holder of My Myford Lathe. If used in the rear toolpost to has to be mounted inverted.

The body is made from two pieces of 6 mm plate, cut on the bandsaw and clamped together then drilled 3.2 mm for M4 tapped holes. The holes on the outside are later drilled 4 mm clear. M4 cap screws are used to both clamp the blade and the two parts together. The holes in the hacksaw blade were drilled with an M4 carbide drill.

I recently had a need for a thin parting tool. So I set to and made this one !

I used a broken hacksaw blade and made a holder for it, the drawing below shows the dimensions that I used.

The holes are there to hold the two pieces together and allow the hacksaw blade to be moved forwards in 5 mm steps. Also the maximum stick out is limited to 20 mm. The whole thing is designed to fit into the front or rear tool holder of My Myford Lathe. If used in the rear toolpost to has to be mounted inverted.

The body is made from two pieces of 6 mm plate, cut on the bandsaw and clamped together then drilled 3.2 mm for M4 tapped holes. The holes on the outside are later drilled 4 mm clear. M4 cap screws are used to both clamp the blade and the two parts together. The holes in the hacksaw blade were drilled with an M4 carbide drill.