01-16-2022, 10:09 PM

The next part on this project was the Crank. This part could have easily been machined out of a piece of 2” round cold roll. But I didn’t want to have the cold roll finish on the outside of the part. I wanted to have a nice machined finish. So I started out with a piece of 3” cold roll. This gave me the opportunity to use my rotary table for the first time.

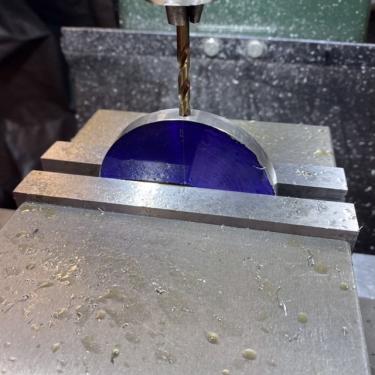

Started out by facing the material to the proper thickness.

Then I drilled and taped the hole for the set screw.

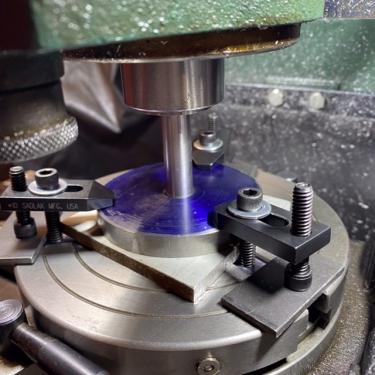

I them put it back in the lathe and drilled and reamed the centre hole to .500

Once that was done I set up the rotary table and set the part up to cut the two notches out.

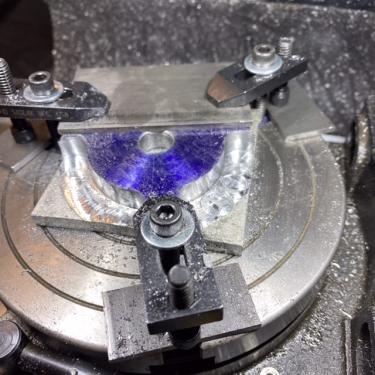

Then the struggle to figure out a good clamping method was on. I did have the part move on me a couple times. Luckily it moved away from the cutter. But I was able to come up with a secure way of holding the part to the rotary table. This allowed me to cut the 2” OD.

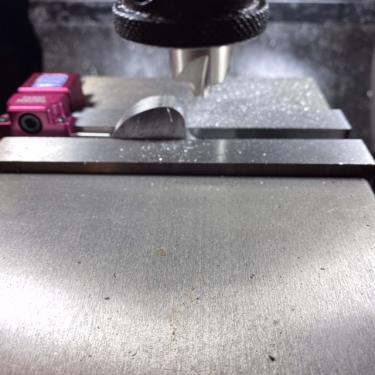

Once that was all done I was left with the general shape of the crank. I just needed to round off the corners at this point.

To round off the corners I was planning on doing it with the rotary table, but decided after talking with Tom G, that was a lot of set up for such a small part. So I decided to pick myself up a 1/4” corner rounding end mill.

Trevor

Started out by facing the material to the proper thickness.

Then I drilled and taped the hole for the set screw.

I them put it back in the lathe and drilled and reamed the centre hole to .500

Once that was done I set up the rotary table and set the part up to cut the two notches out.

Then the struggle to figure out a good clamping method was on. I did have the part move on me a couple times. Luckily it moved away from the cutter. But I was able to come up with a secure way of holding the part to the rotary table. This allowed me to cut the 2” OD.

Once that was all done I was left with the general shape of the crank. I just needed to round off the corners at this point.

To round off the corners I was planning on doing it with the rotary table, but decided after talking with Tom G, that was a lot of set up for such a small part. So I decided to pick myself up a 1/4” corner rounding end mill.

Trevor

Lathe - Craftex CX701, Mill - Craftex B30 Mill/Drill, DRO - blu-DRO