Hi Guys,

After using and trying different tool holders on my Myford Lathe. None of which were particularly outstanding, I decided to make a Norman Patent one as used by Rolls Royce and originally made and fitted to the very early Drumond/Myford lathes. I also found the original patent.

Its very easy to make and in use its easy to see why RR adopted it for use in their development workshops. The tool post is a simple turning job, drilled to fit over the top slide tool fastening bolt. Most of the rest of the work is mostly turning, drilling and threading. The only milling is a simple 13 X 12 mm slot. The original Norman tool holder actually had a 1/2" inch broached square hole to hold the tool.

This picture is of the original Drumond tool holder. It varies a little from the original Norman one, insomuch as it uses a slitted body with a clamping bolt, rather than the split collet of the original one. The advantage of a split collet is that there is an even clamping pressure without any distortion of the tool holder body.

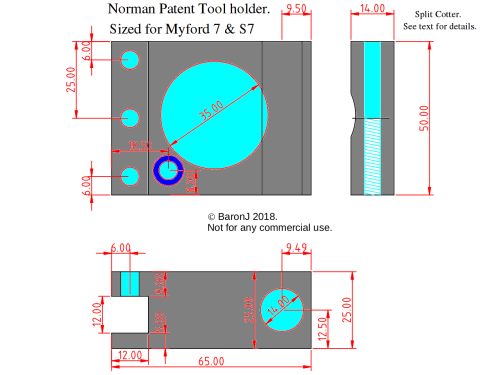

This is the drawing (Coloured) that I did of mine. The only difference is that you have to make the mounting column/post to suit your particular lathe. The post is 35 mm diameter EN1, drilled to suit your mounting bolt.

I used 9/16" diameter rod for the split collet. Two reasons I had length of silver steel/drill rod that size, and a 9/16" reamer. The nearest metric size is 14 mm.

The rod for the split collet was fastened into the drilled and reamed hole in the tool holder block by screws at either end, then the whole block had the 35 mm hole bored to size with the split collet in place. Doing this guarantees the the collet fits the tool post exactly without any slop or looseness. It should be a good sliding fit.

The rod for the split collet is removed and drilled 5 mm diameter all the way through before being cut in half. One half is threaded M6 and the other half is drilled 6 mm clear. A long M6 cap screw is used to close the two half's of the collet. The rest is just drilling and tapping M6 for the clamp bolts and the height adjusting screw. I counter bored for the adjusting screw head.

In this picture, I am using inside calipers to measure the bore for the tool post.

This is the finished product. I also made a new nut to clamp the post to the top slide because the handle kept getting caught in my sleeve. You can also see the back of the split collet and the height adjusting screw.

After using and trying different tool holders on my Myford Lathe. None of which were particularly outstanding, I decided to make a Norman Patent one as used by Rolls Royce and originally made and fitted to the very early Drumond/Myford lathes. I also found the original patent.

Its very easy to make and in use its easy to see why RR adopted it for use in their development workshops. The tool post is a simple turning job, drilled to fit over the top slide tool fastening bolt. Most of the rest of the work is mostly turning, drilling and threading. The only milling is a simple 13 X 12 mm slot. The original Norman tool holder actually had a 1/2" inch broached square hole to hold the tool.

This picture is of the original Drumond tool holder. It varies a little from the original Norman one, insomuch as it uses a slitted body with a clamping bolt, rather than the split collet of the original one. The advantage of a split collet is that there is an even clamping pressure without any distortion of the tool holder body.

This is the drawing (Coloured) that I did of mine. The only difference is that you have to make the mounting column/post to suit your particular lathe. The post is 35 mm diameter EN1, drilled to suit your mounting bolt.

I used 9/16" diameter rod for the split collet. Two reasons I had length of silver steel/drill rod that size, and a 9/16" reamer. The nearest metric size is 14 mm.

The rod for the split collet was fastened into the drilled and reamed hole in the tool holder block by screws at either end, then the whole block had the 35 mm hole bored to size with the split collet in place. Doing this guarantees the the collet fits the tool post exactly without any slop or looseness. It should be a good sliding fit.

The rod for the split collet is removed and drilled 5 mm diameter all the way through before being cut in half. One half is threaded M6 and the other half is drilled 6 mm clear. A long M6 cap screw is used to close the two half's of the collet. The rest is just drilling and tapping M6 for the clamp bolts and the height adjusting screw. I counter bored for the adjusting screw head.

In this picture, I am using inside calipers to measure the bore for the tool post.

This is the finished product. I also made a new nut to clamp the post to the top slide because the handle kept getting caught in my sleeve. You can also see the back of the split collet and the height adjusting screw.