05-01-2021, 08:41 PM

(This post was last modified: 05-01-2021, 09:10 PM by Cross Slide.)

I have the next two parts of the steam engine build complete. The Cylinder and Cylinder Head. They are machined out of 12L14. The material I was starting out with was 1-5/8” OD and would not fit through the bore of my chuck. So this caused me to have a lot of material sticking out of my chuck. Also gave me the opportunity to use my steady rest for the first time.

I started off by facing the end then drilling the centre of the bore. The I reamed that hole to 1/4”. This hole is the hole the piston rod will slide threw.

After that was done I drilled for the piston bore. Once I had the hole large enough I switch to a boring bar.

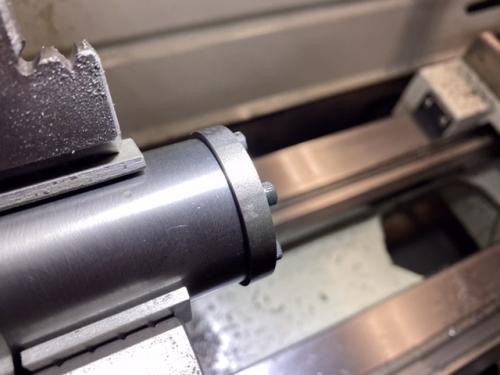

Once I had that done I had to turn down the OD to 1-1/2”. I took TomG’s advice and machined a plug that fit into the bore to accept my live centre. That way I able to remove the steady rest.

At this point I was able to put the part in my mill and drill the bolt circle for the cylinder head to attach.

I then made the cylinder head. Once it was made it was bolted onto the cylinder. It was also bigger OD then the cylinder itself. Since I turned the OD of the cylinder down it was able to fit into the bore of my chuck. I used some aluminum stock to protect the finish on the cylinder from my chuck jaws and turned the OD of the head down to match the cylinder.

Trevor

I started off by facing the end then drilling the centre of the bore. The I reamed that hole to 1/4”. This hole is the hole the piston rod will slide threw.

After that was done I drilled for the piston bore. Once I had the hole large enough I switch to a boring bar.

Once I had that done I had to turn down the OD to 1-1/2”. I took TomG’s advice and machined a plug that fit into the bore to accept my live centre. That way I able to remove the steady rest.

At this point I was able to put the part in my mill and drill the bolt circle for the cylinder head to attach.

I then made the cylinder head. Once it was made it was bolted onto the cylinder. It was also bigger OD then the cylinder itself. Since I turned the OD of the cylinder down it was able to fit into the bore of my chuck. I used some aluminum stock to protect the finish on the cylinder from my chuck jaws and turned the OD of the head down to match the cylinder.

Trevor

Lathe - Craftex CX701, Mill - Craftex B30 Mill/Drill, DRO - blu-DRO