02-09-2015, 12:46 AM

Hi chanse, welcome to the forum.

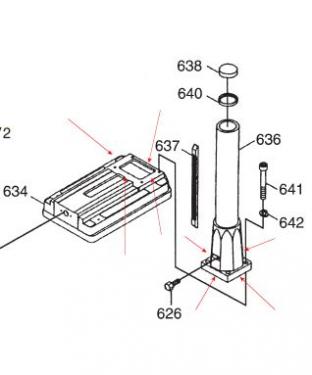

Have a look at this video (skip ahead to 22:30) to get the basic idea of how to use your indicator to check the alignment on your mill. You can ignore all of the adjustment procedures in the video because your mill doesn't have any of the movable adjustments shown. The only way to make changes on your round column mill is by installing pieces of shim stock between the mill base and the rear column flange. (The areas with the red arrows.)

From what I've read in the past, those Grizzly mills are usually close enough to not worry about, provided the contact surfaces are clean and all of the bolts are tightened properly.

Have a look at this video (skip ahead to 22:30) to get the basic idea of how to use your indicator to check the alignment on your mill. You can ignore all of the adjustment procedures in the video because your mill doesn't have any of the movable adjustments shown. The only way to make changes on your round column mill is by installing pieces of shim stock between the mill base and the rear column flange. (The areas with the red arrows.)

From what I've read in the past, those Grizzly mills are usually close enough to not worry about, provided the contact surfaces are clean and all of the bolts are tightened properly.

Willie